The Case for EHSQ Integrated Management Systems

January 5, 2017

Have you ever wondered if there is a better way to manage your organization’s management systems using an Integrated Management System? Silos and disparate systems should be a thing of the past. Between the Quality Management System (QMS), Safety Management System (SMS), and Environmental Management System (EMS), there is abundant opportunity to eliminate inefficiency and duplication of activities especially in more complex organizations with multiple business units.

Whenever you assess or improve the effectiveness of your organization’s management system(s), you need to think about your customers and what they want. It’s easy to get caught up in the minutiae of the day-to-day defects, fire-fighting and improvement projects that can sometimes feel a bit like groundhog day.

Maintaining the customer’s perspective will aid with your decision making. When you’re deciding whether to add another step in a process, introduce a new inspection tool, or seek a new certification like ISO 9001:2015, you should always ask yourself “what would my customer say if I moved forward with a particular initiative if she was standing over my shoulder right now and watched what our company was doing”. Would the customer agree with our decision to allocate limited resources to a new initiative? Would she disagree with investing in the project because of the expected value from the project is questionable? If we improve a process, will it help shorten our delivery times so they can start getting a return on their purchase as soon as possible? We need to be mindful of how our decisions impact our customers in everything that we do – whether B2B or B2C – so that we ensure that customer value is maximized ALL THE TIME and not only when a product or service is in the hands of the customer.

Organizations that lack a critical mass of loyal customers are a ticking time bomb at the mercy of an unforeseen catastrophic failure that will trigger an exodus of customers to competitors. When assessing your customer landscape, organizations can’t be shortsighted and at the value of the individual transaction at a given point in time. Businesses need to broaden their spectrum and consider the entire horizon of the customer’s lifetime and the many interactions a customer will have with your business. The concept of the lifetime value of a customer (CLV) is critical for businesses to understand how the interactions of every employee and business process either deliver value or are sources of waste for their clients.

Customers are concerned about the value they will get from the product or service they buy from your business. If they realize the benefits they expect and the marginal benefits outweigh the costs within a certain time period, then you can check another box on the customer’s checklist of what they expect from you – their supplier – their vendor – their partner. A minimum expectation is that your product or service will not do harm and is safe to use. This becomes even more important because of social media where the voice of the customer lives today. Also, customers will not want to do business with you if your organization has a reputation for being unsafe. Other factors that customers are concerned about include how the company treats the environment and whether they have ethical business practices.

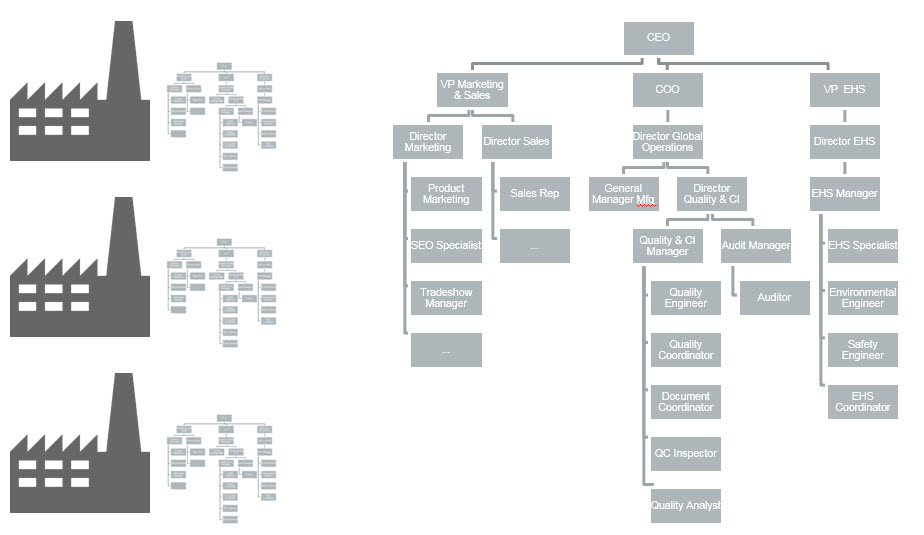

When it comes to Integrated Management Systems (IMS) and we look at typical organizational structures, a few things become apparent. With communication being one of the top challenges in businesses, the conventional silo management system model of today may lead to an organizational structure similar to the below (with additional branches of course not included for illustration purposes). In this structure, communication challenges remain.

Initiatives in one department go unheard of and unnoticed in others as departments are setup with virtual walls that become barriers to progress and value creation. At quarterly and annual company meetings, there may be rumblings of a new initiative going on in the EHS department that the operations team may or may not be aware of. Meanwhile, the Quality team may be working on their own related initiative but the Human Resources, EHS, and Marketing & Sales teams don’t know about it either.

No one likes silos – but we create them all the time. Silos prevent opportunities for learning, knowledge sharing, new perspectives and building strong cross-functional teams and relationships throughout a company. The ability to solve problems with cross-functional teams with varying perspectives helps develop solutions that are far better than any individual or single group could produce on their own. With a siloed approach, companies miss out on opportunities to gain critical insights that other areas of the business would recognize having solved a similar issue previously and sharing lessons learned from that initiative.

How many times have you learned that a problem you were trying to solve in the Quality department was also a problem for the Environment or Health & Safety department? How many times was their finger pointing as to whose problem it was solve? Quality? EHS? Supplier? Sounds familiar doesn’t it.

Why are Integrated Management Systems important? For one, they help companies to remain competitive. Today’s global competitive environment requires companies to continually find ways to innovate, reduce costs, improve operational efficiency, all while exceeding customer expectations and delivering a memorable customer experience. Companies have a few ways to deliver value to customers. They can find ways to differentiate themselves from the competition in novel ways that are hard to replicate or they can focus on efficiency to drive down costs while optimizing internal resources. For example, an organization taking a differentiation strategy approach could focus on providing niche goods and services to customers via new innovative technologies that are very difficult to imitate, the features/functionality of their goods and services, service support capabilities and expertise, and a variety of other possible sources of differentiation. Differentiation is a long term strategy that companies will employ to have a lasting effect for organizations. A differentiation strategy focuses more on innovation whether the innovation is founded in technology, processes, and/or services.

On the other hand, efficiency focuses more on cost reductions and optimizing resource usage regardless if those resources are human capital or capital equipment. Efficiency tries to ensure that an organization’s cost structure is optimized to deliver value to customers based on the goods and services provided. Organizations can leverage Integrated Management Systems to achieve other efficiency gains that are commonly overlooked. An IMS approach eliminates duplication of redundant activities across business units so organizations can free up resources to do what they were hired to do and are passionate about rather than drown in unnecessary busywork.

If any of you have read Chad Kymal’s book or articles on Quality Digest, you’re already aware of the benefits of an Integrated Management System approach can have on your business. In his book, Chad and his team highlight some of the key benefits which include elimination of duplicate processes, 50% savings for management system certification costs, 66% savings on maintaining management system certifications, and 20% savings on 3rd party audit costs. Then there’s the difficult to quantify benefits of what’s underneath the iceberg with silo management systems – improved productivity, increased efficiency, increased knowledge sharing among team members, more effective management systems and freeing up resources to focus on innovation that results in value creation for customers rather than getting caught up with non-value added activities.

With the various management systems in use today, some of the core elements of any successful business include a Quality Management System (QMS), Environmental Management System (EMS), Safety Management System (SMS) and if you’re in the food industry, a Food Safety Management System (FSMS). Rather than operate with separate silos with redundant processes for audits, document management, nonconformances and noncompliances, corrective actions, it is possible to take an integrated approach. An IMS approach also helps to improve the culture in the organization. Seeing all of the management systems as part of one business management system to run the firm introduces systems level thinking. Employees can begin to embrace a design thinking mindset founded on empathy as part of how the organization operates where employees have to think about the impact to other employees and departments in addition to the end customer. The IMS approach teaches everyone in the company to not only think about themselves but the entire system. This can be a powerful organizational capability that leads to new insights and innovations that would be difficult to achieve when viewing systems as independent entities. Once we combine the common elements of the QMS, EMS, and SMS we have what the industry refers to as an Integrated Management System.

Who knows, at some point in the future there probably will be something from ISO that unites these standards together in an IMS guidance document or standard on its own. A first attempt at this is PAS 99. An IMS approach is already the direction that the ISO standards are moving towards as they have adopted the same high level structure so that common requirements can be easily addressed across management systems using the same processes. This really helps prevent organizations from having to re-invent the wheel in the EHS and Quality departments especially.

Basically, Integrated Management Systems focus on consolidation and elimination of duplicate processes that are historically inefficient and resulted from legacy silo management systems. By integrating the management systems across business units, processes, work instructions and forms/checklists and process owners, a more efficient and effective IMS can be realized that will ultimately help place the organization on a strong footing so that it is built to last. The management system becomes that foundational engine that keeps the lights on when no one is home. Areas that are common to these management systems include risk management (risk-based thinking), audits, document management, management review, corrective action, training, and continuous improvement.

It’s our duty to do everything we can to make our businesses successful, safe, produce quality products and services that customers demand with minimal to no impact on the environment. We have a duty to leave the world in a better place for the next generation so that we can transform businesses and environments from barren deserts to communities that resemble an abundant oasis. We should never stop short and settle for today’s silo management system approach. Quality, Environment, and Health & Safety professionals should investigate the opportunity that Integrated Management Systems can bring and start building a business case to eliminate duplicate processes by integrating IMS as a corporate-wide initiative to address a variety of issues relating to inefficiency, unnecessary waste (MUDA), poor use of human and capital resources, lack of visibility for corporate-wide performance, frustrated employees, lost profits, etc.

Going after anything worth pursuing requires skilled team members, persistence, strategy, and a strong culture. Don’t give up on achieving something great like an IMS that will provide your organization, your customers, humanity and the Earth with a multitude of benefits that will stand the test of time.