From Paper to Digital: The Future of Incident Reporting

October 17, 2024

Building a strong health and safety system requires extensive knowledge, training and well-established processes, which can often be complex to implement. Fortunately, digital tools and advanced technologies are simplifying this process. Companies worldwide are turning to technological solutions to boost productivity, reduce risk, protect their workforce and improve their bottom line.

One example of this technological shift is to upgrade from a paper and Excel-based system to EHS software. Why? Paper and Excel are prone to errors, cumbersome to manage and offer limited visibility into incidents, especially if they occur across locations. In contrast, EHS software centralizes data from various systems and locations, providing real-time insights and streamlining communication—critical in high-risk industries. Ready to make the switch? This blog article will explain how.

The Downsides of Manual Paper-Based Incident Reporting

Imagine you’re overseeing multiple sites, relying on paper and Excel-based systems. Every incident report or safety audit requires manual updates, making it time-consuming and difficult to centralize data. As reports pile up, delays in communication and decision-making become inevitable, leading to increased risk of incidents. Siloed information makes errors and compliance gaps more common, exposing your organization to penalties.

Instead of focusing on implementing effective safety processes, you spend valuable time tracking down data across locations. This inefficiency makes it nearly impossible to scale your health and safety management system, weakening your safety culture. It’s no wonder you’re looking for a change.

Why Digital Incident Reporting is the Future of Safety Management

Now, imagine having instant access to real-time incident data, allowing you to monitor safety risks as they happen. With digital solutions, you no longer need to wait for manual reports or updates. Instead, you can track and address potential issues immediately, preventing small problems from escalating into major incidents. This real-time visibility empowers you to make faster, more informed decisions, improving your overall safety management.

You also benefit from instant notifications and alerts, ensuring that key stakeholders are informed of incidents or safety concerns the moment they arise. This rapid communication speeds up the response process, minimizing downtime and keeping your workforce safer. With centralized data storage, all your safety-related information is organized and accessible from anywhere, giving you the ability to analyze trends, reduce human errors and maintain compliance across multiple locations. By adopting digital tools, you can improve safety outcomes across your entire organization. Here’s how to put this program into action.

How Intelex Transforms Incident Reporting for the Better

With the right digital tools and features, you can ensure that incident data is captured quickly and accurately, improving both response times and overall safety performance. In industries where fast, informed decisions are crucial, these capabilities help drive proactive safety management and reduce costly errors.

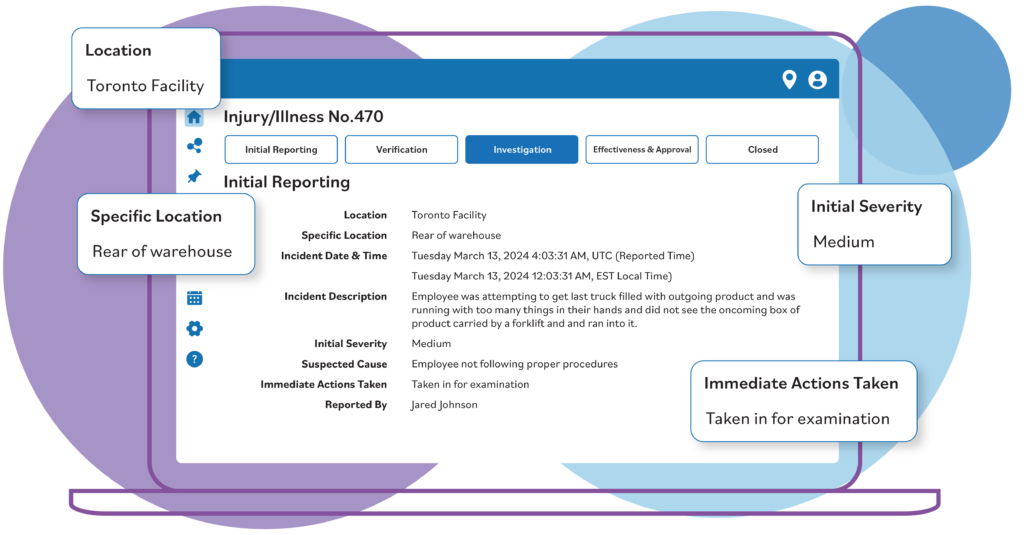

Mobile Access: Intelex’s Safety Incident Management software provides mobile access, enabling field workers and remote teams to report incidents on the go. This ensures that critical information is captured immediately, no matter the location, reducing delays in reporting and response times. Even in areas with limited connectivity, the software’s offline capabilities allow users to record incidents and sync data once back online, ensuring no details are missed.

Real-Time Data Collection: With real-time data collection, Intelex allows safety professionals to instantly log and track incidents as they happen. This improves response times and ensures that decision-makers have access to the latest information for better risk management.

Automation: The software automates notifications, workflows and reporting, streamlining the entire incident management process. Automated alerts keep teams informed, while workflows ensure that incidents are addressed efficiently without manual follow-up.

Customizable Forms: Intelex offers customizable incident reporting forms, allowing organizations to tailor them to their industry-specific requirements. This flexibility ensures that critical data points are captured, enhancing the relevance and usefulness of each report.

Data Integration: Intelex’s Safety Incident Management software integrates seamlessly with other software systems, such as HR, ERP and CRM, creating a unified platform for managing safety data. This connectivity improves efficiency, simplifies compliance tracking and provides a comprehensive view of safety performance across the organization.

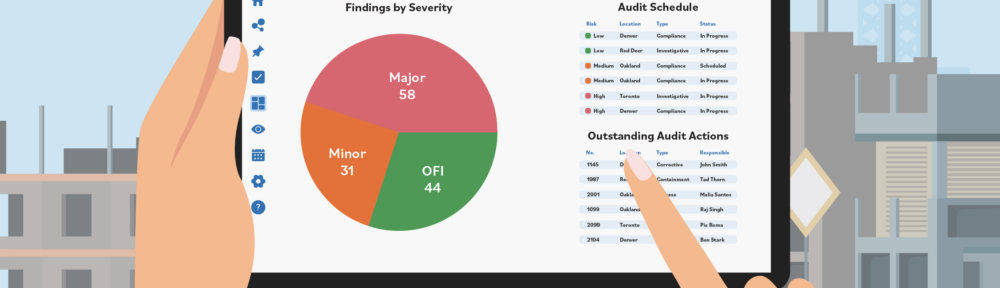

Insights and Dashboards: Intelex’s software offers robust insights and dashboards that provide safety professionals with real-time visibility into incident trends and safety performance metrics. These customizable dashboards allow users to track key performance indicators (KPIs), monitor compliance and identify areas for improvement. By consolidating data into easy-to-read visual reports, decision-makers can quickly assess risks, spot patterns and drive proactive safety measures.

Case Study – How Going Digital Helped SGS Cut Workplace Incidents by 70%

SGS, a leading global inspection, verification, testing and certification company, operates in more than 2,600 locations with over 96,000 employees worldwide. Managing safety across such a vast network was a challenge, especially when relying on paper-based systems. SGS successfully transitioned from manual reporting to digital, dramatically improving its safety performance using Intelex’s Safety Incident Management software.

Before Intelex, SGS faced challenges with their paper and Excel-based reporting. Mikki Teodoro, from SGS Global Operations Integrity (OI) Communications and IT, explains: “Naturally, there was no traceable visibility of incident investigations and corrective actions, which was a big challenge. When Intelex went live, we were able to gather more reliable data.”

The impact of this digital transformation was clear: between 2009 and 2021, SGS saw significant improvements in its Lost Time Incident Rate (LTIR) and Total Recordable Incident Rate (TRIR). The most notable decrease occurred between 2014 and 2015, when SGS first deployed Intelex. By 2016, SGS had fully integrated its Health, Safety and Environment (HSE) performance reporting, consolidating data from nine different sources into one dynamic, real-time report using Intelex. This shift has been instrumental in enhancing safety, improving response times and providing actionable insights across the organization.

Why It’s Time to Go Digital with Intelex

Moving to a digital incident reporting system offers numerous benefits, from real-time access to data and instant notifications to centralized storage and automated workflows. These features not only improve response times but also reduce the risk of errors, streamline compliance and enhance safety performance across organizations. As shown by companies like SGS, the transition from manual processes to digital reporting can lead to significant improvements in safety outcomes, helping you to prevent incidents and create a safer work environment at your company.

Now is the time to make the shift. Discover how Intelex’s comprehensive solution can transform your safety management processes—watch the Intelex Incident Reporting software demo and experience the difference for yourself.