Why EHS Teams Choose Point Solutions (And Why There's a Better Way)

As a safety manager, you play a lot of different roles. Every day, you’re a detective, problem solver, mentor, policy enforcer and more. Over my 42-year career, I spent much of my time strapped to a pager or some kind of electronic leash, always

Latest Posts

- Health & Safety Management

Digital Transformation in EHS: Expert Tips for Getting It Right

Expert advice for leading a successful digital...

- Intelex News and Updates

Tap Into Knowledge, Tips, and Support in the Intelex Community

Learn about the Intelex Community. A hub exclusive to customers to connect with peers, get expert tips, solve problems faster, and get more value from your...

- Environmental Sustainability and ESG Reporting

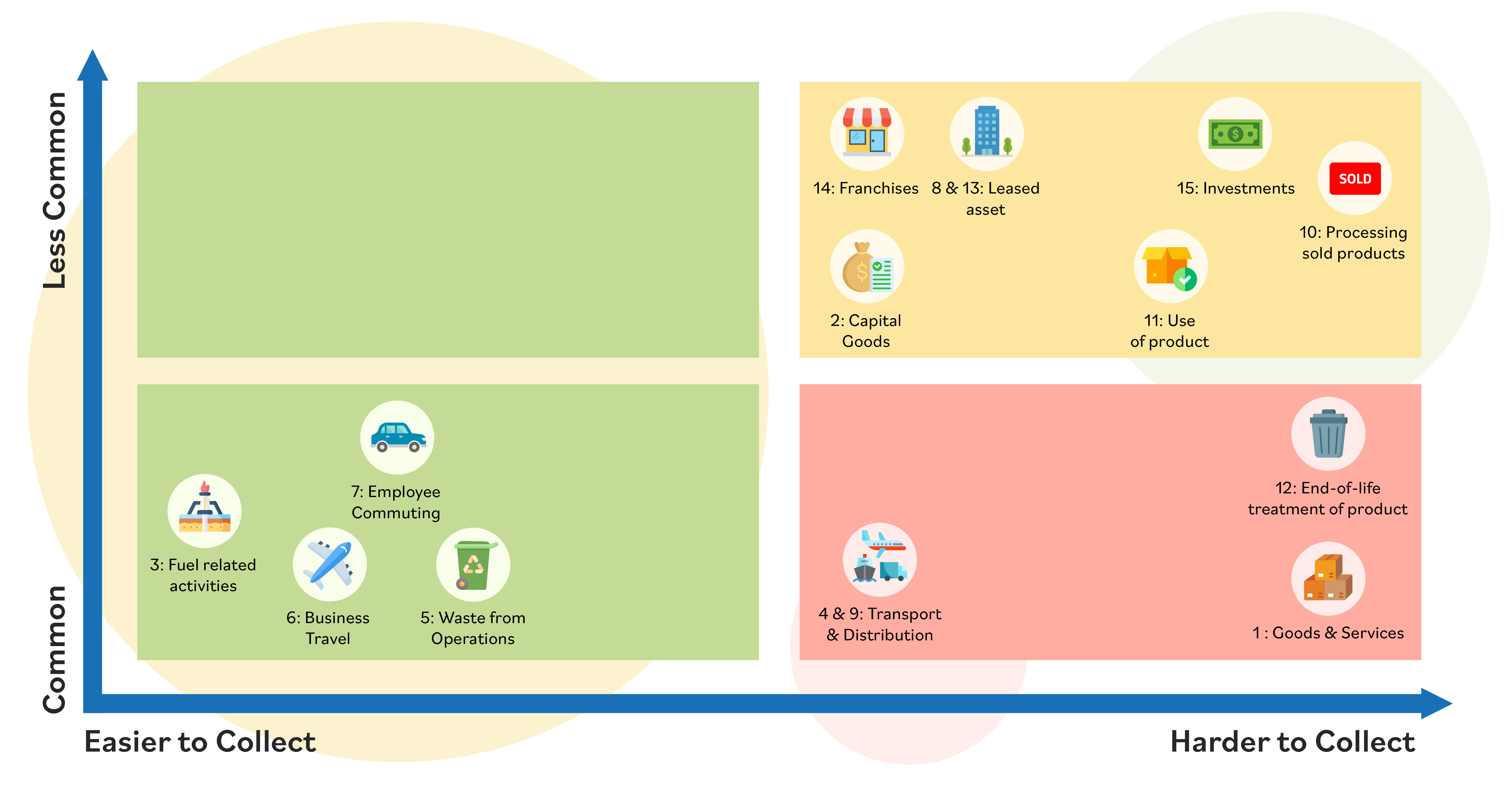

Why Scope 3 Emissions Are the Next Big ESG Hurdle—and How to Tackle Them

Scope 3 emissions are the most complex—and increasingly mandatory—part of ESG reporting. See how you can tackle them with the right data, tools, and...

- Industry Trends and Insights

All In Together: A Personal Call to Action for Construction Safety Week 2025

Safety isn’t a department—it’s a shared commitment. In this personal message for Construction Safety Week 2025, Scott Gaddis calls on the industry to embrace true collaboration, close safety gaps, and leverage technology that empowers every worker to...

- Health & Safety Management

Culture vs. Compliance: Building a Sustainable and Balanced Safety Mindset

Discover strategies to align compliance and culture for stronger, safer workplaces. Learn how EHS leaders can drive engagement, accountability, and...

- Health & Safety Management

The 5 Biggest Safety Imbalances Holding Organizations Back — And How to Fix Them

The father of modern management, Peter Drucker, once said, “Efficiency is doing things right; effectiveness is doing the right things.” This distinction is particularly relevant in safety...