Safety in the Supply Chain: How Technology Mitigates Risk

April 13, 2022

A conversation with Trevor Bronson, Strategic Development Manager at Intelex Technologies, on how the fragility of supply chains have been exposed in the wake of recent global uncertainty and what can be done at organisational level to improve their robustness.

In February 2022, Trevor Bronson virtually presented to a large Health & Safety Matters audience on the best practices around promoting supply chain safety, including identifying what is required to keep a suppy chain operational, resilient, flexible and compliant. (If you want to watch the webinar “Safety in the Supply Chain: How To Lower Risk and Increase Resiliency Among Contractors And Suppliers,” click here.) In this Q&A, Trevor discusses the risk to supply chains, techniques to improve safety management within them and the impact technology can play in facilitating supply chain operations.

Q1. Can you tell us a bit about your background?

My background is mostly EHS, but from multiple vantage points. I’ve been a safety practioner, worked in environmental compliance, and even spent a few years as an EHS technology analyst for an indpenendent analyst firm. Experiencing the world of EHS from so many different angles afforded me the opportunity to understand exactly how I wanted to contribute to this industry in the long term, and that’s advancing the role of technology.

Q2. Most recently, you presented at a Health and Safety Matters-hosted webinar on the topic of safety in the supply chain. Can you give a brief summary of what safety in the supply chain encapsulates and why this topic is of relevance to cross industry organisations today?

Safety in the supply chain is all about risk management. If your business is relying on suppliers that don’t take safety seriously, you’re liable to experience accident-related production and distribution delays. You’re also likely – especially in this day and age – to take a reputational hit if the public realizes you knowingly disregarded known gaps in your suppliers’ safety protocols and performance. Since most industries rely on a supply chain, every business needs to consider and mitigate these risks.

Q3. You spoke about the impact of the pandemic on supply chains in the webinar. How has COVID-19 affected supply chain operations over the last two years and what are your predictions on how these affects will continue in 2022?

COVID-19 made everyone realize just how vulnerable supply chains are. The hard lessons learned since 2020 are not going to be forgotten anytime soon, so I predict that businesses will continue to deepen their understanding of their supplier network to assess its vulnerability to health and safety-related issues, whether they are localized or global. This isn’t related to events either. It can also include regulatory burdens and enforcement tendencies.

Q5. Supply chains are becoming more fragile. We see this frequently across the media in stories of shortages of product globally. Why is this and what can be done to improve their robustness?

They’re fragile because modern supply chains are optimized for cost and speed. This means that, in pursuit of those objectives, they can get incredibly complex. Complexity means more points of failure, and when one card in a house of cards slips… To improve their robustness, businesses need to do all they can to understand and mitigate the risks they are exposed to. This means looking beyond inventory or distributiuon channel risks into risks like safety performance and compliance status.

Q6. One of the themes that you spoke on in the webinar is contractor safety. How, if at all, does this differ from an organisation’s own safety practices, proceses and expectations?

Contractor safety is an exercise in accountability, visibility and engagement. Internal employee safety is too, but there is an extra layer of difficulty when you don’t control their training, the tools they have access to, insurance policies, the architecture of their safety program or the maturity of their safety culture. In essence, contractor safety is all about ensuring that the contractor’s overall safety posture meets or exceeds the expectations you have of your regular staff.

Q7. What advise would you give an EHS manager (or similar) who is looking to improve the safety of their end-to-end operations?

Always start with building a thorough understanding of those operations and where the biggest risks lie. The EHS department is rarely flush with cash, so be intentional in how you allocate resources for maximum impact. I’ll also say that the lowest-hanging fruit is usually communication-related.

Q8. Can you talk through what role technology can play in improving the safety processes and procedures in a supply chain across any industry?

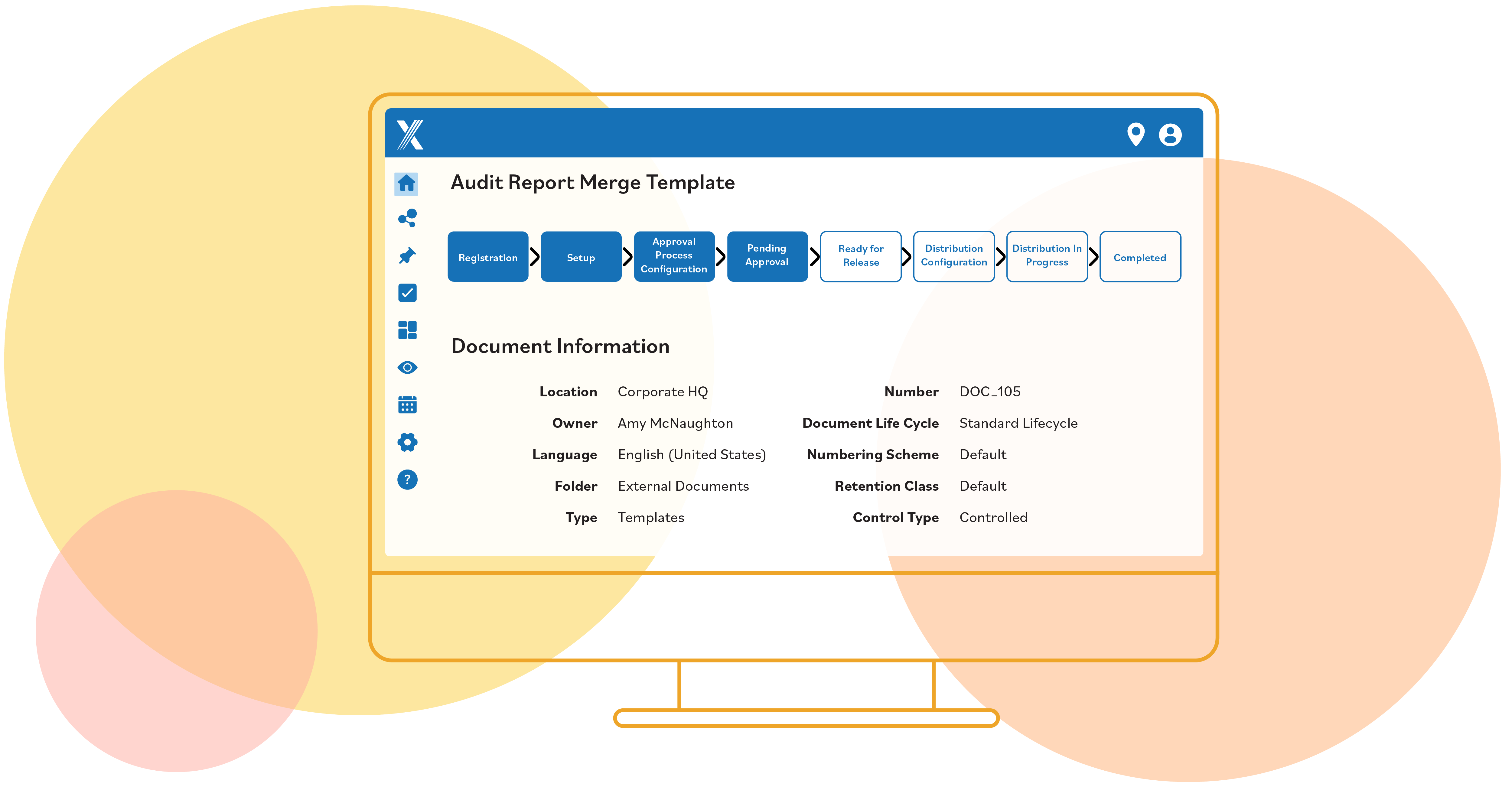

Technology can play such a major role in improving contractor and supply chain safety. It can allow third parties to effectively communicate their safety qualifications and performance before you begin working with them, it can make it easier for them to receive training on your processes and procedures, it can allow you to be aware of issues at your supplier immediately and alter plans accordingly… Really, the list goes on and on. Keeping with the theme of this interview, technologies like EHS software, pre-qualification software/services, werable safety devices or virtual reality (VR) training all facilitate visibility and mitigate risk.

Q9. What advice would you give to an organisation that recognises its safety processes need improvement to better support the supply chains that it is part of?

They should reach out to their supply chains to better understand expectations and learn what they have done in the past to close the gaps. You don’t need to reinvent the wheel; you just need to take a methodical approach to improving your program and making the most of the tools and technioques that will allow you to do that.

Q10. To conclude, what are your predictions on how safety culture will evolve over the next decade in line with technology advancements?

Technology will enable safety culture to be easier to cultivate and maintain. Communication will be easier, training will be more contextual, hazard identiofication will be more instantaneous and an undersdtanding of exactly what goes into a world-class safety program will become clearer and more ubiquitous. Technology will also help businesses demystify the relationships that exist between safety and other parts of the business, such as supply chain, manufacturing, quality, financial performance and so on, meaning safety culture will have an even bigger emphasis since the long-tail impacts of a strong safety culture, as well as a weak one, will be known and quantifiable.