Why Compliance Audits Matter: A Real-World Lesson from our VP of Safety

November 7, 2024

10 minute read

Throughout my career leading safety in a paper mill, deadlines were always tight, production demands were always high and preventative maintenance schedules sometimes lagged because we consistently tried to keep the mill operating.

Regrettably, safety compliance audits were missed as production demands increased. It was not long before I noticed small safety issues cropping up in the operations areas, but I figured they were minor and could wait. After all, the machines were sturdy, and production was a priority.

Warning signs ignored

One hot summer day, one of our workers was operating the paper machine. This massive piece of machinery had rollers that ran at high speeds and pressed pulp sheets into smooth, flat tissue paper.

Over a few days, the worker had noticed an odd grinding noise coming from one of the rollers housed within the machine frame. He’d mentioned it to his supervisor, who assured him they’d get around to it soon, but production couldn’t slow down, and he told the worker to keep the machinery going.

The incident

Later that day, however, as the worker was feeding pulp into the machine, the noise grew louder and the machine suddenly jolted, sending vibrations through the entire operating floor.

Startled, workers backed away just as a section of the machine roll shifted. Loose bits of pulp, bearing parts and various bolts and nuts flew, narrowly missing a group of workers standing behind a control panel.

A near miss. And a wake-up call

We were lucky. We avoided serious injuries to our workers by mere seconds, by just a few feet of distance, but the close call left us all shaken. That night, we all went home, realizing something had to change.

The following day, we assembled the team and fully agreed that this was not a minor miss but a serious near-miss event that could have been fatal.

We decided that a safety compliance audit was in order.

What the audit revealed

The auditors took their time inspecting each piece of machinery and every procedure, recording and documenting their findings meticulously.

When the auditors reached the failed paper machine roller, they discovered that the rollers were dangerously worn, creating excess friction at the bearing housing.

The audit revealed other issues, too.

- The mill’s conveyor belts, used to carry heavy pulp loads, needed repair.

- Several safety procedures were not updated per the compliance schedule.

- Some workers hadn’t received refresher training on emergency shutdown procedures, which could have been critical in an incident.

Changing the culture

Stunned by the audit results, our leadership team immediately committed to revamping our value for safety compliance auditing.

From then on, our culture towards audits started changing.

- Compliance audits were scheduled quarterly.

- Additional monthly maintenance inspection checks to ensure the machines ran safely.

- Workers were also given updated training, empowering them to report any potential hazards without fear of slowing down production.

My lesson from this was that our culture improved because of our transparency and honesty in looking inward at our mistakes and collaboratively working on a solution.

Compliance auditing became a central focus, and workers felt renewed pride and security in their work. The entire team, from management to the shop floor, was invested in the new protocols, knowing they were there to protect the workers and the work environment.

Why audits matter

Beyond merely satisfying regulatory requirements, safety compliance audits are proactive measures that help organizations identify unsafe practices, faulty equipment and compliance gaps before they escalate into serious incidents or costly penalties.

By consistently conducting safety audits, companies not only protect their workforce from harm but also promote a culture of safety, which enhances employee morale, boosts productivity and reduces the likelihood of accidents.

This blog post delves into the importance of occupational safety compliance audits, outlines how they are conducted and highlights their pivotal role in creating safer, more efficient workplaces, prioritizing employee well-being and regulatory compliance.

What is a safety compliance audit?

A safety compliance audit thoroughly reviews an organization’s safety policies, procedures, equipment and facilities. The goal is to ensure compliance with local, state and federal safety regulations, like those mandated by OSHA (Occupational Safety and Health Administration) and the HSE (Health and Safety Executive.)

Safety auditors focus on identifying non-compliance issues, evaluating the effectiveness of safety programs, and ensuring accurate documentation. Their primary objective is identifying and addressing potential safety risks before accidents or injuries occur.

Key objectives of a safety compliance audit

- Identify Physical Hazards: Spot unsafe conditions or processes.

- Evaluate Safety Protocols: Ensure effectiveness and compliance with guidelines.

- Evaluate Safety Protocols: Ensure effectiveness and compliance with guidelines.

- Prevent Incidents: Minimize Risks to avoid injuries, penalties and downtime.

Why are compliance audits important?

Ensures regulatory compliance

Organizations must comply with safety regulations, such as OSHA standards, to avoid fines, legal issues or operational shutdowns. Regular audits ensure companies stay compliant with evolving regulations.

Prevents workplace accidents

Audits help identify hidden hazards, such as faulty equipment or unsafe processes. Early detection allows companies to take proactive measures, reducing the chance of accidents and protecting employees’ health.

Fosters a safety-first culture

Conducting regular audits shows a company’s commitment to safety. It encourages employees to adopt safe behaviors and report potential hazards, strengthening a safety- conscious culture where everyone contributes to maintaining a secure workplace.

Boosts operational efficiency

Unsafe conditions can lead to accidents that disrupt operations and cause costly downtime. Addressing these issues through regular audits helps companies avoid such interruptions, leading to improved workflow and reduced compensation claims.

Protects reputation and brand

A strong safety record enhances a company’s reputation. Prioritizing safety earns trust from employees, clients and customers, while accidents due to non-compliance can harm a company’s image and result in negative publicity.

Components of a successful safety compliance audit

- Planning and Preparation: Review current safety policies, past incidents and relevant regulations to tailor the audit to the organization’s risks.

- On-Site Inspection: A physical walkthrough of the facility to check for hazards like malfunctioning equipment, blocked exits or inadequate personal protective equipment (PPE).

- Document Review: Examine incident reports, training records and maintenance logs to ensure proper record-keeping and adherence to safety protocols.

- Employee Engagement: Interact with employees to gain insights into potential risks not captured in documentation and evaluate the effectiveness of safety programs.

- Audit Report and Action Plan: Create a detailed report outlining non-compliance issues and corrective actions with assigned responsibilities and timelines after the audit.

- Follow-Up Audits: After corrective measures are implemented, follow-up audits confirm the success of improvements and ensure ongoing compliance.

How Intelex is transforming safety audits

Intelex can streamline compliance auditing in multiple impactful ways. Here’s how it enhances the efficiency, accuracy and consistency of safety audits:

Centralized audit management and documentation

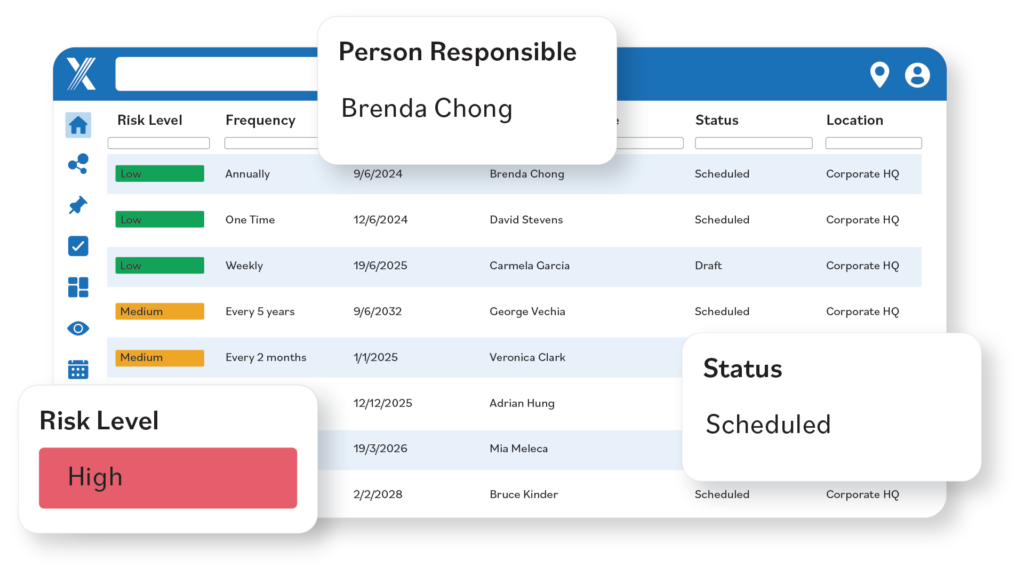

Intelex provides a centralized system where all audit information—schedules, documentation, checklists and past reports—can be stored and accessed easily. This reduces the time spent searching for previous audits or organizing documentation, ensuring all audit-related data is in one location, easily searchable and standardized.

Automated scheduling and reminders

Intelex allows users to set up automated scheduling for audits based on compliance needs or internal schedules. Automated reminders help ensure that audits occur on time, minimizing the risk of missed deadlines. These reminders can be customized and sent to relevant personnel, reducing reliance on manual tracking and communication.

Customizable checklists and templates

Intelex enables safety managers to create customizable checklists and templates that reflect specific safety standards, regulatory requirements and internal compliance protocols. This standardization helps ensure consistency across audits and allows team members to perform audits more thoroughly, covering all necessary safety requirements.

Mobile accessibility for on-the-go audits

With mobile support, Intelex allows auditors to conduct real-time audits on-site using tablets or smartphones. This functionality enables immediate data entry, photo capture and issue documentation, reducing paperwork and enabling faster data collection and reporting.

Real-time reporting and analytics

Intelex generates real-time reports that provide insights into safety performance metrics, recurring issues and areas needing attention. With these analytics, management can identify patterns, track audit outcomes over time and proactively address high-risk areas, ultimately driving continuous improvement in safety compliance.

Automated issue tracking and corrective action management

When issues are identified during audits, Intelex can automatically generate corrective action tasks and assign them to relevant personnel. The platform can track these corrective actions from assignment to completion, ensuring accountability and quick resolution of non-compliance issues.

Compliance with regulatory standards

Intelex is designed to help organizations comply with various regulatory standards, such as OSHA, ISO 45001, etc. The software includes features to help align audits with these regulations, ensuring that organizations can meet external audit requirements and avoid potential penalties.

Improved transparency and accountability

Through its centralized dashboards and detailed audit trail capabilities, Intelex provides visibility into the status of all compliance activities. This transparency makes it easy for stakeholders to monitor progress and confirm that audits are completed as scheduled. This transparency fosters accountability at every level, from team members to management.

Historical data and audit trends analysis

Intelex maintains a repository of all past audits, making it easier to analyze historical data and identify trends. This feature allows organizations to see where improvements have been practical and where ongoing issues might require additional resources or focus.

Enhanced employee engagement and participation

Intelex’s user-friendly interface encourages broader team engagement, allowing employees at different levels to access audit findings, contribute to safety observations, and participate in corrective actions. This inclusion helps foster a proactive safety culture and improves buy-in for compliance initiatives.

A crucial priority for Forterra is maintaining their ISO certifications—9001, 14001, 45001, 50001, and 6001. Intelex’s Audit Management Software has been invaluable in supporting this goal, helping Forterra streamline and strengthen their internal compliance processes. Click to read more.

Conclusion

Occupational safety compliance audits are far more than just a regulatory checkbox—they are a strategic investment in the well-being of employees and the organization’s long-term success. These audits help businesses stay aligned with ever-evolving safety standards, like those enforced by OSHA, while providing a structured way to identify and address potential hazards before they lead to accidents, injuries or costly shutdowns. By taking a proactive approach to safety, organizations reduce the likelihood of workplace incidents and foster a culture of trust and responsibility where employees feel valued and empowered to report risks and follow safety protocols.

Incorporating modern technology into the audit process further elevates its effectiveness. Digital tools such as mobile auditing apps, cloud-based safety management platforms, IoT sensors and AI-powered analytics allow organizations to streamline their audits, improve real-time data collection and gain deeper insights into potential safety risks. These innovations help businesses move from a reactive posture—responding to incidents after they occur—to a preventative mindset, where risks are identified and addressed before they can lead to harm.

Safety compliance audits are crucial for maintaining legal compliance, operational efficiency and reputation management. A solid commitment to safety can reduce downtime, prevent costly penalties and build a positive brand image among employees, clients and the public. As businesses evolve, those prioritizing safety through regular audits and cutting-edge technology will safeguard their workforce and position themselves for sustainable growth and success in an increasingly competitive marketplace. Regular compliance audits aren’t just a regulatory necessity but a strategic investment in a safer, more productive workplace.

Ready to see how Intelex simplifies safety compliance? Watch our product demo to discover how real-time reporting, mobile capabilities, and automated tracking can transform your safety audits and help create a safer workplace.