ISO 45001 and ANSI Z10: Essential Guides for Effective Safety Management Systems

July 26, 2022

Industry standards exist to help set the foundation for a safety management system. For those who may not have a system in place or are looking to take an existing safety management system (SMS) to the next level, standards offer a guiding blueprint for the key and necessary components and practices. Two of the most common and ubiquitous are the International Organization for Standardization’s ISO 45001 and the American National Standards Institute’s ANSI Z10.

ISO 45001 is described as the world’s first international standard for occupational health and safety systems. It provides a framework for improving health and safety performance and is intended to control the factors that may result in injury, illness or death on the job. ISO 45001 is also described as process-based and considers risks and opportunities. The standard explicitly mentions mental health as an element that should be protected by the program.

Another noteworthy feature of ISO 45001 is that stakeholders in the safety program should include those beyond employers and employees and target the local community potentially impacted by the activities of an organization. ISO 45001 is intended to encourage the perception of health and safety, not as a stand-alone department or activity, but as a practice integrated across all areas and activities and supporting overall business success. Among other things, that means integrating environment, health and safety (EHS) roles with other business support functions.

The stated purpose of ANSI Z10 standard is to provide organizations with an effective continuous improvement approach to occupational health and safety performance. The general structure and content of ISO 45001 and ANSI Z10 are similar, but there are areas where Z10 is more comprehensive and slightly different than certain sections of ISO 45001. One of the most important statements Z10 makes is that, whenever practical, an organization’s SMS should be integrated into already existing business practices. The Z10 standard focuses mainly on the strategic aspects of how of health and safety policies are carried out but does not spell out things like detailed procedures or job instructions.

Z10 is based on United States laws and regulations, business practices, labor relations and health and safety approaches, whereas ISO 45001 considers business practices, approaches to health and safety, legal and regulatory requirements from international ISO member countries. The information in the chart below comes from the American Society of Safety Professionals (ASSP) and compares these two standards.

| ANSI Z10 | Or | ISO 45001 |

|---|---|---|

| Comprehensive, systems-based standard | Primary Focus | Global Standard for OSH management systems |

| – Aligned with ISO 45001 for organizations seeking dual compliance – Gold Standard of OHSMS in the US. | Unique Characteristics | – Helps create a global foundation of worker safety standards that can be used by all global supply chains – Covers contractors and subcontractors in every country within these supply chains |

| Not currently used by certification bodies | Certification | Developed with the goal of certification |

| – Easier to implement – Based on US business practices, legal system and union/management relations | Ease of Use | With 64 countries involved, consideration has been given to a wide range of cultures, business practices and elgal systems |

| Only available in English | Language | Available in many languages |

| Provides flexibility in tailoring its requirements to an organization’s health and safety risks | Flexibility and Scalability | Does have some flexibility, but some sections are more specific |

| Includes a strong emphasis on health | Occupational Health | Not as focused on occupational health as the Z10 standard |

| Greater emphasis on worker participation | Worker Participation | More specific on worker participation |

| – Guidance and Implementation Manual available – ASSP offers a guidance document for smaller organizations at no cost | Implementation and Support | – Guidance and Implementation Manual available – ASSP sells the US adoption of the standard it costs much less than the international version |

“I probably like Z10 better (than ISO 450001). If you lay them side-by-side, they’re fairly comparable,” says Scott Gaddis, the vice president and global practice leader for safety and health at Intelex Technologies. “ISO (45001) allows you the ability to do what you think are the best things to do. It’s almost written as performance guidelines.

“Z10 is also written as a performance guideline, but it explains what (the processes) should look like. It’s almost like an audit (that explains) here’s what your auditor will be looking for. I like how Z10 goes after what I call the predictable elements of a management system.”

Free Help is Also Available for ANSI Z10 and ISO 45001

If IS0 450001 or ANSI Z10 aren’t the frameworks your organization feels equipped to follow as a template for its SMS, there is other simpler and free guidance available to help you get started. Malcolm Jacobs, the senior director for environmental health and safety at TDX Holdings in Anchorage, Alaska recommends looking to your workmen’s compensation insurance provider.

“If you have a good program you’re saving them money,” he says. “They may have sample programs for different activities and some even have guidance to share on developing your hazard analysis. They’ll also have a team that could come to your company to observe and make recommendations for your ergonomic programs.”

Jacobs adds that insurance companies are often willing to do a safety audit of your organization which you can then use to measure against your own audit for comparison. During their audit, insurers may make a list of deficiencies which you can then correct. Some insurance companies offer safety training that they’ll often provide onsite for your employees.

“Insurance companies offer quite a bit,” he says. “It just depends on your provider and it’s always worthwhile to get on the phone and speak with them. When you purchase insurance, they certainly ask you a lot of questions so it’s only fair that you can ask them questions, too.”

OSHA’s Voluntary Protection Program or VPP is another great option and a good place to start when thinking about a SMS.

“Employing your country or state OSHA organization is an excellent resource,” Jacob says. “If you look at their check sheet for building a VPP program, it follows the Z10 and ISO 450001 standards closely. The program also gets you involved with other companies that have been through VPP and have safety management systems in place. Many are willing to share their audits with you and provide feedback.”

And some final advice from Jacob for those looking to implement a safety management system:

- Review relevant information that’s available on safety management systems.

- Look at your organization and determine what’s currently in place, what’s needed or what can be improved (See “10 Steps to Take Your Safety Management System from Good to Great.”)

- Build relationships with your organization’s management and with your workforce.

- Understand the mission of the company and where it is going in the future and make sure your plan incorporates your company’s business vision.

- Benchmark and follow the best practices of other companies that already have and utilize a SMS.

How does the integration of the ISO 45001 or ANSI Z10 standards into existing business practices typically impact the overall workflow of an organization?

Integrating ISO 45001 or ANSI Z10 standards into existing business workflows can have a substantial impact on an organization. It typically requires a thorough review of current practices and procedures to ensure they align with the guidelines set out by the standards. This process might involve revising safety policies, improving employee training programs and enhancing reporting and emergency response protocols. The integration can lead to a more proactive approach to identifying and mitigating risks, which can improve overall employee well-being and potentially increase operational efficiency. However, the specific impacts can vary widely depending on the nature of the business, its current safety practices, and the level of change required to meet the standards.

What specific areas does ANSI Z10 cover that are considered more comprehensive than ISO 45001, and can you provide examples of how this comprehensiveness is reflected in an organization’s safety management practices?

ANSI Z10 is considered more comprehensive in certain areas compared to ISO 45001, particularly concerning its alignment with U.S. laws, regulations, and business practices. While the blog post doesn’t detail these areas, it implies that ANSI Z10 may offer more explicit guidance on how to integrate safety management with other business functions and might provide clearer expectations for auditors. This could mean that ANSI Z10 delves deeper into aspects such as employee participation, hazard prevention, and emergency preparedness, offering more concrete examples or templates for organizations to follow. For an organization, this might translate to a more detailed roadmap for implementing and maintaining a safety management system that aligns closely with U.S. standards and expectations.

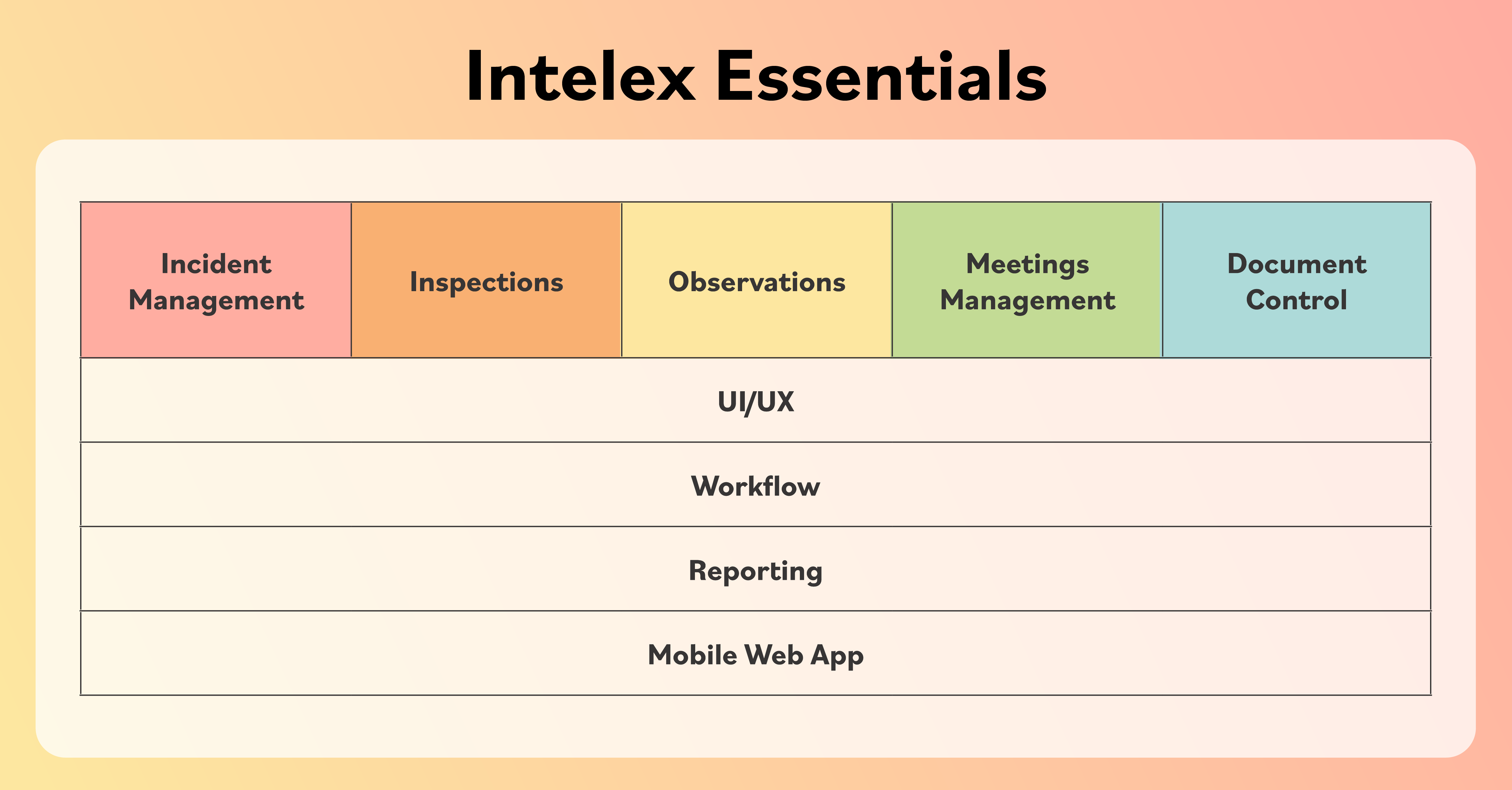

Take the next step in optimizing your safety management system. Register for a custom demo to see how Intelex can help you seamlessly integrate ISO 45001 or ANSI Z10 into your operations.