Preventing Accidents in the Fall Zone: OSHA Guidelines and Safety Tips for Suspended Loads

November 12, 2018

In almost every industry, a load of some kind is being lifted, manipulated, lowered or carried in a way that poses risk to workers. The U.S. Bureau of Labor Statistics reports that there are more than 50,000 “struck by falling object” recordable injuries every year in the United States. That’s one injury every 10 minutes caused by a dropped object in the workplace.

Learn how to create a safer, compliant workplace with OSHA’s fall zone requirements, best practices for handling suspended loads, and effective fall zone management.

What is the OSHA Fall Zone?

The fall zone as defined by OSHA is “the area including, but not limited to, the area directly beneath the load in which it is reasonably foreseeable that partially or completely suspended materials could fall in the event of an accident.” OSHA goes on to state that standing under a suspended load is prohibited and that “while the operator is not moving a suspended load, no employee must be within the fall zone, except for employees (who are): engaged in hooking, unhooking or guiding a load; engaged in the initial attachment of the load to a component or structure…”

As a safety practitioner, there’s a simpler approach. Whether the load is suspended and static or moving in any motion, respect the fall zone because your life and the lives of others depends on it.

Best Practices for Staying Out of the Fall Zone

One of the biggest concerns working with overhead loads is judging what is a safe distance from the load. The size of the fall zone should expand as the complexity of the lift is understood and planned. OSHA and other regulatory agencies mandate that carrying loads over people should to be avoided, so it’s reasonable that the fall zone moves along the direction of travel to ensure measures are taken to eliminate exposure.

Load height is another critical factor, because as load height grows, so does the radius of the fall zone.

Load size, weight, shape and rigging should all be considered as well as issues like operator knowledge and skill, environmental conditions and equipment. There are a lot of variables to consider in ensuring safe load handing but be sure to think about it 360 degrees around the load.

Here are a few key safety tips to consider:

- Avoid carrying loads over people: This is required to protect people from the hazard of a falling load due to inadvertent failure of a crane, hoist, forklift or other machinery, or if the operator makes an error.

- Establish a Safe Radius: At a minimum, stay at least 10 feet radius from where a suspended load could fall if there was failure. If a load is suspended higher, increase the radius.

- Understand Load Type and Equipment: Every load—whether handled by crane, forklift, or hoist—poses unique risks. Consider variables like load height, size, weight and shape, along with operator skill, environmental conditions and equipment stability.

- Plan the Path of Travel: If there’s a boom crane involved, understand the full radius of the load swing.

- Account for Environmental Conditions: Weather factors like wind, illumination, or freezing temperatures affect load stability and must be considered.

- Training and Awareness: Conduct training for workers in the fall zone, establish communication systems for noisy environments, and create awareness of planned lifts during shifts.

- Exclusion Zones: In areas accessible to the public, set up exclusion zones to prevent fall zone entry.

Situational Safety Awareness

Finally, working around or near suspended loads requires a great level of situational awareness, whether you are the operator who is lifting and/or carrying the load, or you are working around or near the load being lifted.

Situational safety awareness is having a good understanding of:

- what is happening around you

- the work environment you are in

- what is happening around you at the moment

- where your work will take you during the next moment

- and, most important, anyone or anything around you that can threaten your safety.

To improve your situational awareness, make a habit of consciously assessing your work environment and regularly stopping to perform a quick mental assessment of it. If you feel you are in any immediate danger, or if others are introducing unwarranted risks that could affect your safety, stop and immediately begin to improve the safety of the worksite.

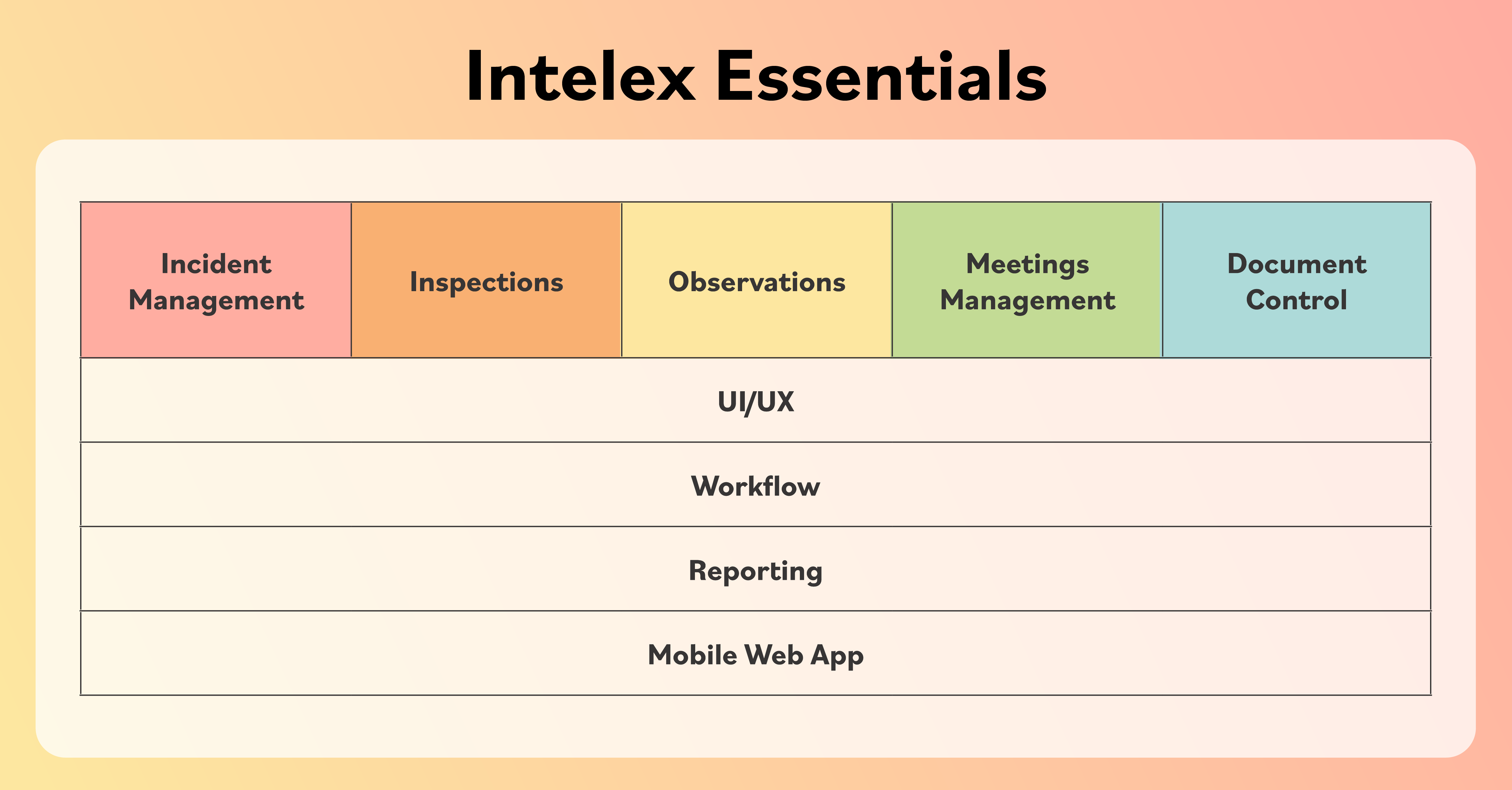

How Intelex Health and Safety Management Software Can Help

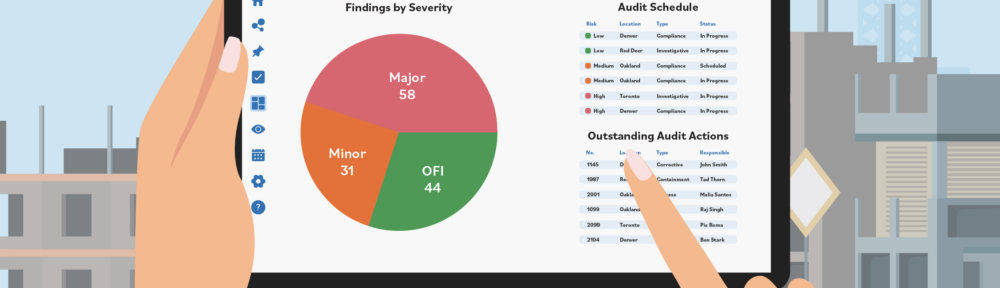

For organizations aiming to strengthen their safety culture and OSHA compliance, Intelex Health and Safety Management Software offers a powerful solution. Intelex helps ensure safe operations around fall zones and overhead loads through digital risk assessments, incident tracking, and reporting features.

- Risk Matrix Designer: This tool enables companies to assess, document and manage risks associated with fall zones and suspended loads, improving hazard identification and preventive measures.

- Safety Inspection Software: Conduct thorough inspections of walking-working surfaces and other high-risk areas. Through mobile access, workers can efficiently document hazards and implement corrective actions.

- Incident Management: Quickly report and analyze incidents involving suspended loads, enabling safety teams to identify root causes and prevent recurrence.

- Corrective and Preventive Action (CAPA) Software: CAPA tools track corrective actions taken following incidents or near misses, ensuring continuous improvement in line with OSHA guidelines.

Using Intelex software, organizations can enhance OSHA compliance, minimize the risks associated with fall zones, and build a proactive safety culture that protects workers.

Conclusion

In every industry, preventing accidents in the fall zone is critical to worker safety. By understanding OSHA guidelines, respecting the fall zone and leveraging safety tools like Intelex, organizations can reduce risks and create a safer work environment.

For more insights on injury and illness prevention, download our free Insight Report, Reporting Injuries and Illnesses: Are You Collecting the Right Data for OSHA Recordkeeping? Gain a deeper understanding of OSHA’s recordkeeping requirements, common reporting pitfalls, and how technology can improve data accuracy and compliance.