Sustainable Waste Management: Cory’s Role in Advancing ESG

May 5, 2022

Cory’s goal is to ensure London has a safe, clean and sustainable way of managing its recyclable and non-recyclable waste. The company uses a river-based infrastructure to help London manage its recyclable and non-recyclable waste, making the city cleaner and safer.

Founded in the mid–late 1800s and incorporated 125 years ago in 1896 as W.M. Cory & Son, the company has evolved from a coal distribution company on the River Thames into one of the UK’s leading waste management, recycling and energy recovery companies. Their vision is to be partner of choice for sustainable waste management throughout London and the South East of England.

The company’s vision is to be the partner of choice for sustainable waste management for London, with the objective of preventing unnecessary material being buried in a landfill or exported out of the UK for others to deal with. By focusing on recycling and resource recovery, Cory keeps materials in use for as long as possible and helps grow London’s circular economy.

The company’s sustainability strategy should help deliver this vision. In the context of the global climate emergency, Cory wants to play its part in delivering a net zero carbon future by:

- Expanding its services to divert more waste from landfills.

- Committing to lower carbon design and construction for new build projects.

- Developing a heat network.

- Exploring technologies and processes to help decarbonize EfW and its operations.

Because Cory has been operating on the River Thames for 125 years, the company has an intrinsic connection to the river’s health and value as a local resource. The company’s ambitions include:

- Improving air quality across all sites.

- Enhancing environmental performance through use of an effective and continually improving environmental management system.

- Maximizing resource efficiency.

- Improving understanding of local biodiversity issues and ecological management at the company’s site in Belvedere.

How Cory Powers Sustainability and Cuts Carbon

Cory receives around 750,000 tons of non-recyclable black bag waste a year, enough to fill St Paul’s Cathedral 12 times! Eighty-nine percent of that waste comes to one of the company’s four riverside waste transfer stations. As part of that process:

- 150,000 tons of carbon has been saved by not sending waste to landfills

- 731,000 tons of non-recyclable ‘black bag’ waste diverted from landfills

- 501GWh of electricity generated, enough to power 160,000 homes, and

- 100,000 trucks kept off London streets by using the river to move material cross a city, substantially reducing carbon emissions while providing an essential public service.

“We have targets to hit net zero carbon by 2050, and when you model what this means for shorter timeframes, it is important to have reliable and accurate datasets for actual and historic energy usage,” said Mark Greenwood, Director of Health, Safety, Environment & Quality Assurance at Cory.

Leveraging Intelex Software to Drive Efficiency and Build Trust

Due to nature of the business – sorting, containerizing and moving waste – the greatest need for digital technology intervention was within the functions that support the business: HSEQ, Finance, IT and HR. The organization needed clarity and visibility on what was going on in the frontline operations, especially as it is simply not possible to be everywhere at once. In addition, there was a need to foster a culture of continuous improvement and awareness – with an emphasis on building trust between management and workers.

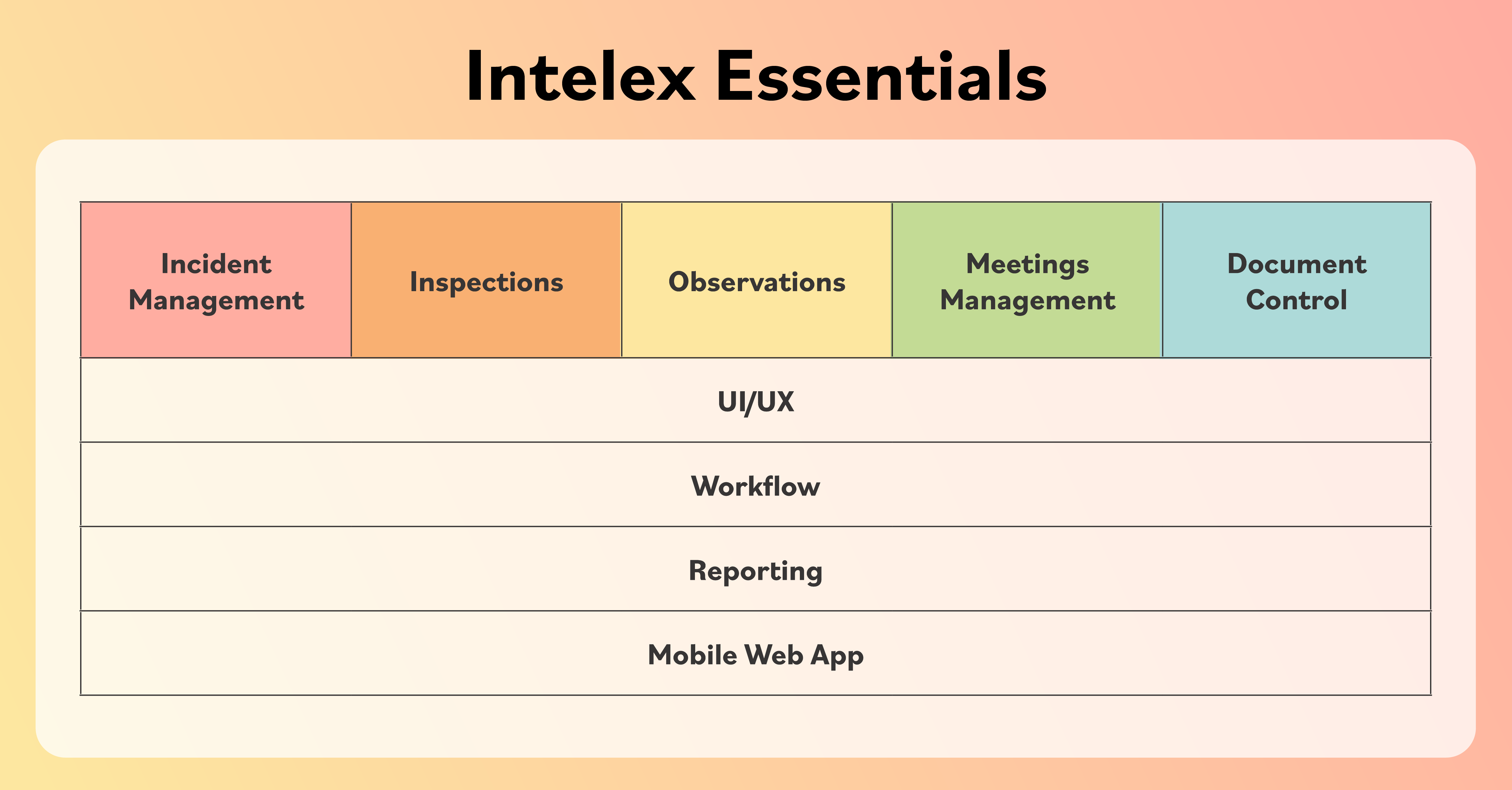

The team implemented Intelex’s Sustainability Performance Indicators (SPI) application (now called ESG Management Software), Safety Observations Management Software and Incident Management Software.

Intelex’s Audit Management Software, Inspection Management Software and Job Safety Analysis (JSA) Software are currently in the process of being implemented.

A key driver for the Intelex system was that it enabled the Cory team to have the flexibility to make workflows and processes match those that they were already comfortable with within the organization.

As a river-based logistics operation, Cory has very specific reporting requirements which are different to those required for land-based sites, so having a system that the team members are able to configure to their specific needs was vitally important.

Enhancing Efficiency and Resilience Through Integrated EHS Systems

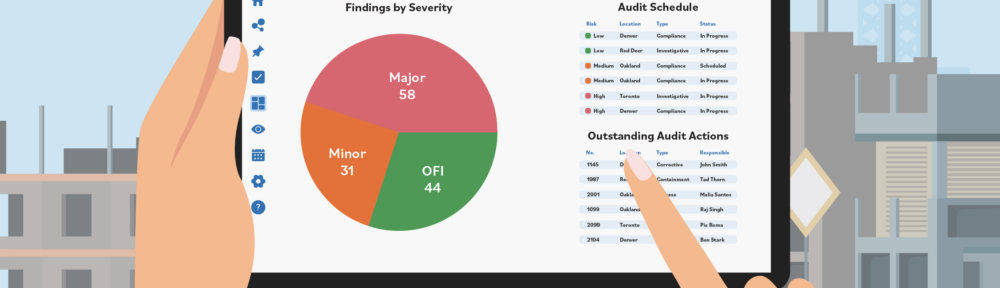

The roll out of SPI, Safety Observations and Incident Management has increased Cory’s ability to analyze incident data and as importantly, understand what has happened and why.

The ability to link records together and have the applications “speak” to each other is proving to be invaluable. For example, a record created in JSA can be linked with data in Audit Management and Inspection Management, providing valuable insight and improved efficiency. The Cory team are now able to see errors in real time which importantly allows them to address the fundamental and underlying issues. The team has also seen a reduction in the administrative and information management overhead they previously encountered, while continuing to demonstrate compliance across the organization.

“Our success is measured by feedback from our customers and suppliers,” said Greenwood. “We strive to ensure that these relationships are characterized by outstanding service, delivered responsibly.”

But there is another benefit from applying EHS processes and systems, particularly the ISO management systems, he added, which is that the organization is more resilient and ultimately, more efficient, when processes are reliable, predictable and—where appropriate—standardized. “This thinking underpins our integrated management system, which is the foundation upon which all our EHS processes run.”

Learn more about Cory and its implementation of Intelex by downloading the case study.