Stand Down for Fall Safety: Addressing Fall Hazards in Construction

May 6, 2021

The National Safety Stand Down to Prevent Falls in Construction is an annual event in the United States, which raises fall hazard awareness across the country to stop fall fatalities and injuries. In 2024, the event occurs on May 6-10 and is led by the US Occupational Safety and Health Administration (OSHA).

Each year, OSHA publishes a top 10 list of the most frequently cited violations it has recorded. The list for 2023 is largely unchanged from 2023, suggesting that little progress has been made addressing the most common workplace incidents, four of which are related to fall protection: fall protection (general requirements), ladders, scaffolding and fall protection (training requirements). OSHA recorded 7,271 violations in fall protection, making it the number one violation for the 13th consecutive year.

Fatalities caused by falls from heights continue to be a leading cause of death for construction employees, accounting for 395 of the 1069 construction fatalities recorded in 2022. Those deaths were preventable. The National Safety Stand-Down raises fall hazard awareness across the country to stop fall fatalities and injuries.

“Falls from height are the leading cause of death for construction workers,” said fall safety expert Thom Kramer, P.E., CSP, a member of the Board of Directors of the American Society of Safety Professionals (ASSP). “Workers can face risks on roofs, above floor openings and even at lower levels or when using PPE that deceptively feels safer. But no matter the task, workplace fatalities are preventable.”

What is a Safety Stand-Down?

A safety stand down is a voluntary event for employers to talk directly to employees about safety and incident prevention. Any workplace can hold a stand down on fall safety by taking a break to focus on fall hazards and reinforcing the importance of fall prevention, including engineering controls, training and personal protective equipment.

Employers at companies where employees are not exposed to falls from height can also use this opportunity to have a conversation with employees about falls on walking and working surfaces – on average, slips, trips and falls cause nearly 700 fatalities per year – as well as the other job hazards, protective methods and the company’s safety policies and goals.

How to Conduct a Safety Stand Down on Fall Hazards

Conducting a fall safety stand down is a proactive measure to prioritize workplace safety and address the risks associated with falls effectively. Planning is crucial; identify the most pressing fall hazards relevant to your workplace, considering factors like recent incidents, near misses or emerging risks. Engage with supervisors, safety officers and employees to develop an agenda that addresses these concerns while aligning with the unique needs of your workforce and operations.

Communication is key; ensure all employees are well-informed about the details of the fall safety stand-down in advance. Clearly articulate the purpose, agenda and expectations for participation, emphasizing the importance of active engagement. Utilize various communication channels such as meetings, email, posters and digital platforms to reach everyone effectively and encourage their involvement.

During the fall safety stand down, facilitate engaging discussions, training sessions or interactive activities focused on preventing falls. Utilize visual aids, real-life examples and hands-on demonstrations to enhance understanding and retention. Encourage open dialogue, address concerns and emphasize the importance of individual responsibility for fall prevention.

In addition to the fall safety stand down activities, it’s essential to provide ongoing education and training to employees on fall prevention strategies. The American Society of Safety Professionals (ASSP) offers valuable resources, including online fall protection courses, to enhance knowledge and skills in this critical area. By leveraging such resources, organizations can further empower their workforce to proactively identify and mitigate fall risks, ultimately fostering a safer work environment for all employees.

How Intelex Can Help Enforce Fall Safety

Intelex, a leading provider of health and safety management software, offers valuable tools and solutions to support organizations in their fall safety initiatives. Here’s how Intelex can help enhance fall safety:

- Risk Assessment and Management: Intelex’s platform allows construction organizations to conduct comprehensive risk assessments to identify fall hazards across their operations and job sites. By centralizing data and leveraging advanced analytics, organizations can prioritize risks, track mitigation efforts and ensure compliance with regulatory requirements.

- Training Management: Intelex’s training module enables construction organizations to develop and deliver customized fall safety training programs. From initial onboarding to ongoing refresher courses, employees can access relevant training materials, complete certifications and track their progress to ensure they have the knowledge and skills necessary to prevent falls.

- Microlearning Bulletins: Intelex offers microlearning bulletins on fall safety topics, providing quick and digestible information to construction workers. These bite-sized resources cover key concepts, best practices and safety tips, allowing workers to reinforce their knowledge and stay informed about fall prevention strategies on the go.

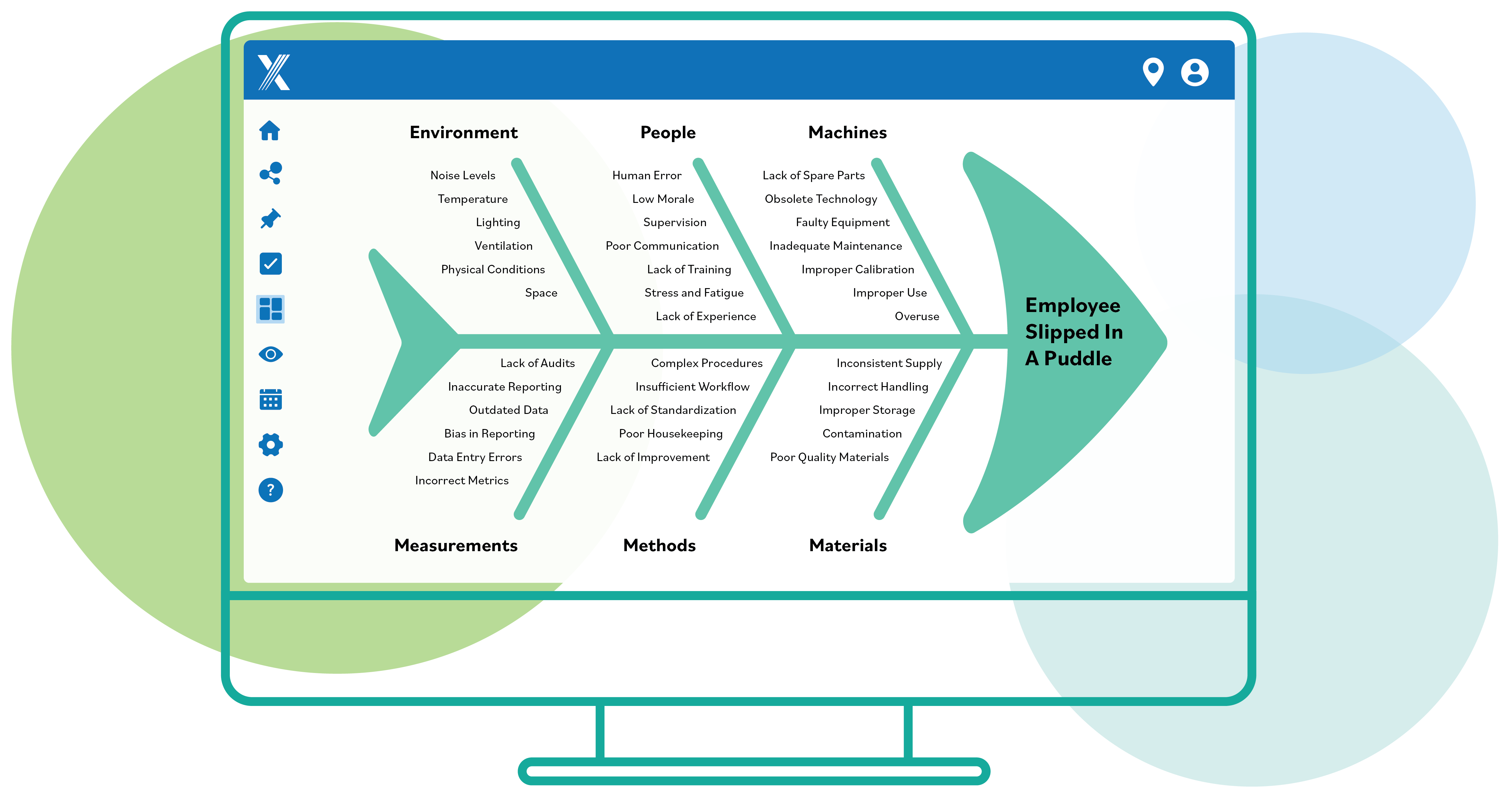

- Incident Reporting: In the event of a fall-related incident, Intelex’s incident management module streamlines the reporting and investigation process. By capturing critical data in real-time, construction organizations can analyze root causes, implement corrective actions and prevent similar incidents from occurring in the future.

- Inspections and Audits: Intelex’s inspection and audit tools empower construction companies to conduct regular inspections of fall protection equipment, worksites and procedures. By automating inspection workflows, organizations can identify deficiencies, schedule corrective actions and verify compliance with safety standards.