NCR vs CAPA: Safety and Quality Management

May 3, 2019

8 minute read

Building a great workplace means keeping your people safe and maintaining high quality. It’s important to make sure these two goals support each other.

Two key tools can help: understanding when things don’t go as planned (nonconformance) and knowing how to fix problems and prevent them from happening again (CAPA, or Corrective and Preventive Actions).

In this post, we’ll explain NCR vs CAPA, what these concepts mean, how they relate to each other, and why they are important for building a culture of ongoing safety and quality improvement.

NCR vs CAPA: A short explanation

Nonconformance, or nonconformity, refers to failing to meet specified requirements, whether customer expectations, statutory or regulatory mandates, or internal standards like ISO 9001 protocols. Nonconformities are often found through inspection, audit or investigation. These failures can occur in any process or product and may indicate deeper systemic issues within an organization.

CAPA is a step-by-step way to look into current or possible nonconformities. It helps find and remove the root causes, so problems don’t happen again and risk is managed proactively. Corrective Actions fix current problems, while Preventive Actions try to stop future ones.

Blaine Hoffman, the producer of the SafetyPro Podcast, emphasizes the necessity for safety professionals to integrate their understanding across different departments. He suggests, “Do a couple of tours of duty in the quality department or in engineering and look at how they solve problems. What all safety management systems ultimately require is the ability to integrate with other business processes. You need to determine that before even considering implementing a safety management system. (Ask yourself) do we have the infrastructure built to support the systems approach? That’s key.”

When organizations address NCRs and CAPAs, they protect their employees, reduce risks, and find ways to improve and work more efficiently. Managing safety and quality together is more than just meeting rules—it’s a smart way to build long-term success and resilience. Knowing how nonconformance and CAPA work together is key for any organization that values high safety and quality standards.

NCR and CAPA: A longer explanation

By clearly defining and separating nonconformance and CAPA, organizations can better handle safety and quality problems. This helps solve issues right away and prevents them in the future. Taking this approach improves products and processes and supports goals like ongoing improvement, employee well-being, customer satisfaction, and ethical leadership.

In safety and quality management, nonconformance means not meeting certain requirements, like customer expectations, rules, company standards, or international guidelines. It includes any time a process or product does not meet the set criteria, which calls for quick and corrective action.

Nonconformance reports (NCRs) record these problems, explaining how and why they happened, what impact they had, and how to prevent them in the future. These reports help organizations find issues faster, improve communication, and make it easier to track and fix problems.

Related: Nonconformance Reporting Software Demo

Corrective and Preventive Actions are different from nonconformances because they focus on fixing problems now and stopping them from happening again. CAPA covers both correcting current issues and taking steps to prevent future ones. This approach solves problems and makes the system stronger by finding root causes, taking action, and checking that the solutions work. It helps make sure changes last.

The main goal of dealing with nonconformance is to handle problems quickly, lower the cost of poor quality, reduce risks like warranty or recall costs, and stay in line with standards like ISO 9001 and ISO 14001. In contrast, CAPA aims at a deeper engagement with the problem, intending to uncover and address the systemic issues that allow nonconformances to occur, thereby preventing their recurrence.

When to use NCR or CAPA

To further clarify when to use NCR or CAPA, consider these three critical questions:

- Can the problem be fixed immediately within the process without significant consequences?

- Then a nonconformance should be reported.

- Did the problem result in significant negative outcomes such as waste, scrap or customer dissatisfaction?

- Then the root causes will be understood through CAPA.

- Is the issue indicative of a more systemic problem or likely to recur?

- Then both a nonconformance report and CAPA should be conducted to understand which part of your system factors to focus on and fix to ensure sustainable change.

The answers to these questions help you choose the right response. This could mean writing a detailed nonconformance report, making a quick fix, or starting a full CAPA process.

The connection between safety and quality management

Safety and quality management are more than just meeting rules—they are key to long-term success. Both help reduce risks and support ongoing improvement, so their connection is important for running a great operation.

Both systems share the goal of identifying, analyzing, and reducing risks in processes and products. Addressing nonconformances and using CAPAs are important steps that improve product quality by meeting standards and expectations, and also make the workplace safer by preventing incidents and accidents.

For example, when a manufacturing defect (a quality issue) is detected, it not only affects product integrity but also poses potential safety risks to end users and handlers, which should be called out. Similarly, a safety incident caused by failing equipment could point to a quality issue in maintenance processes or the original manufacturing. Addressing these issues through CAPA involves investigating root causes and implementing measures to prevent recurrence, thereby improving both quality and safety.

Related: Corrective and Preventative Action Reporting Software Demo

Organizations that adopt an integrated approach to safety and quality management often see several benefits:

- Enhanced Compliance: More effective alignment with regulatory requirements and standards, reducing legal and financial risks.

- Improved Efficiency: Elimination of duplicated efforts and conflicting objectives between safety and quality teams.

- Increased Employee Engagement: A safer workplace and a commitment to quality can lead to higher job satisfaction and morale.

- Greater Customer Satisfaction: Higher quality products and safer practices lead to improved customer trust and loyalty.

- Cost Reduction: Addressing safety and quality together can reduce the costs associated with accidents, defects and non-compliance penalties.

Best practices for Intelex NCR and CAPA Software

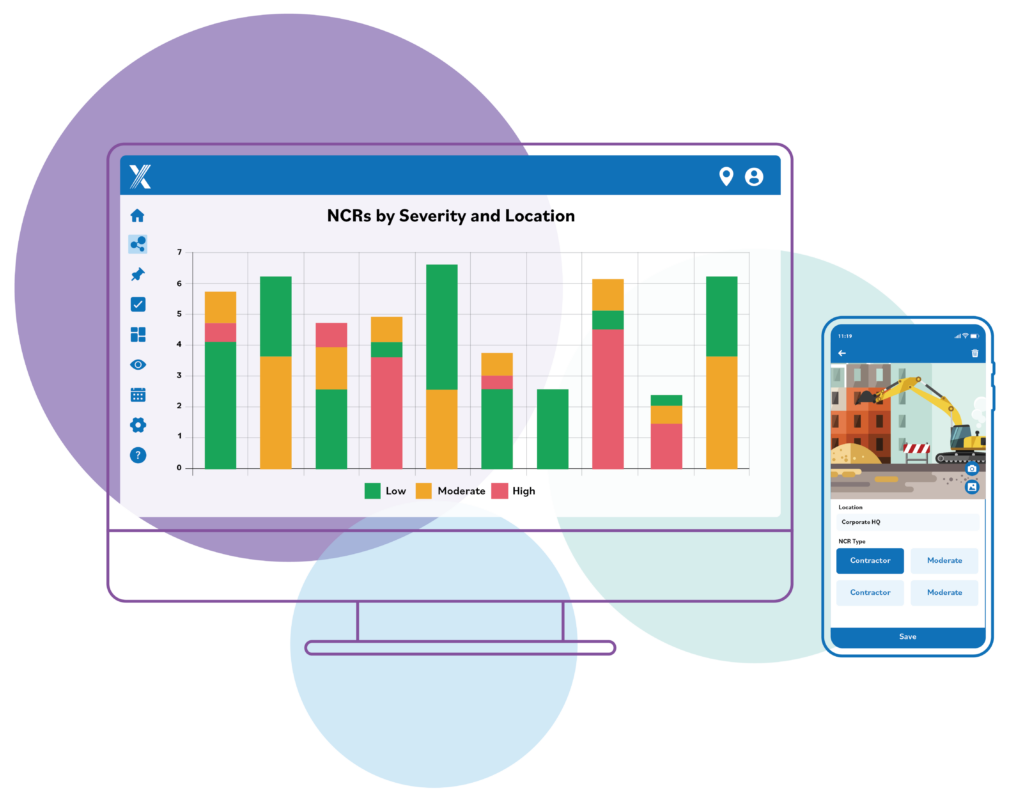

Managing nonconformances and CAPAs well is essential for keeping high standards of quality and safety. Tools like Intelex Nonconformance Reporting and CAPA software can make these processes better. Here are some practical tips to get the most out of your nonconformance and CAPA systems.

Start by setting clear procedures for identifying, documenting, and addressing nonconformances. Create standard criteria for what counts as a nonconformance in every department so employees can spot issues easily.

Use Intelex to record all details of a nonconformance, such as time, location, description, and any immediate corrective actions. Automated workflows in Intelex help make sure nonconformances are handled quickly by sending reports to the right people and alerting them to urgent issues.

Use structured methods like the 5 Whys, Fishbone Diagram or FMEA (Failure Modes and Effects Analysis) in Intelex to find the root causes of nonconformances, not just the symptoms.

Based on these findings, create corrective and preventive actions, and use Intelex to assign tasks and set deadlines to ensure everyone is accountable. After taking action, regularly check if the solutions work by doing assessments and audits, and use Intelex’s tracking and data tools to review results and make changes as needed.

Focusing on employee training and involvement in safety and quality efforts is essential. Build a culture of safety and quality by including employees, encouraging open communication, and letting them share their ideas. Recognizing and rewarding those who contribute can inspire others to keep high standards.

Use technology to support continuous improvement by using Intelex’s reporting and analytics to spot trends in nonconformance and CAPA data. This analysis gives insights into where processes and products can improve. Intelex also works with other management systems to strengthen safety and quality efforts.

Ensure organizational success through NCR and CAPA

Safety and quality management are closely connected, with each supporting the other to help organizations succeed. By addressing nonconformances and using strong CAPA procedures, organizations stay compliant, reduce risks, improve efficiency, and protect their reputation.

Using best practices for managing nonconformance and CAPA, like using Intelex and encouraging continuous improvement and employee involvement, is key for strong business operations. These steps help organizations solve problems early and prevent them from happening again, creating a resilient way of working. By following these strategies, organizations can keep improving and gain a competitive edge.

Ready to enhance your organization’s safety and quality processes? Create a custom demo of Intelex Nonconformance Reporting and CAPA software today. Discover how these powerful tools can streamline issue resolution, prevent recurrence, and drive continuous improvement.