Why It’s Critical to Get Lockout/Tagout Right

March 22, 2018

In December 2022, a 29-year-old worker at a Hostess Brands LLC facility in Chicago suffered the amputation of a fingertip while reassembling a pump. This preventable injury occurred because the company failed to enforce proper Lockout/Tagout (LOTO) procedures, allowing the equipment to start unexpectedly during maintenance. Following a U.S. Department of Labor investigation, Occupational Safety and Health Administration (OSHA) inspectors cited the company for multiple violations, resulting in proposed penalties of $298,010. You do not want this to happen to your company or your employees.

Mandated by law in various countries, LOTO ensures that equipment is properly shut down and incapable of being restarted before the completion of servicing or maintenance activities that could endanger workers, such as unjamming equipment, changing a machine setting, quality checks or machine changeovers. OSHA’s standard for The Control of Hazardous Energy (29 CFR 1910.147) outlines essential measures for controlling different types of hazardous energy, establishing employer responsibilities and mandating comprehensive worker training.

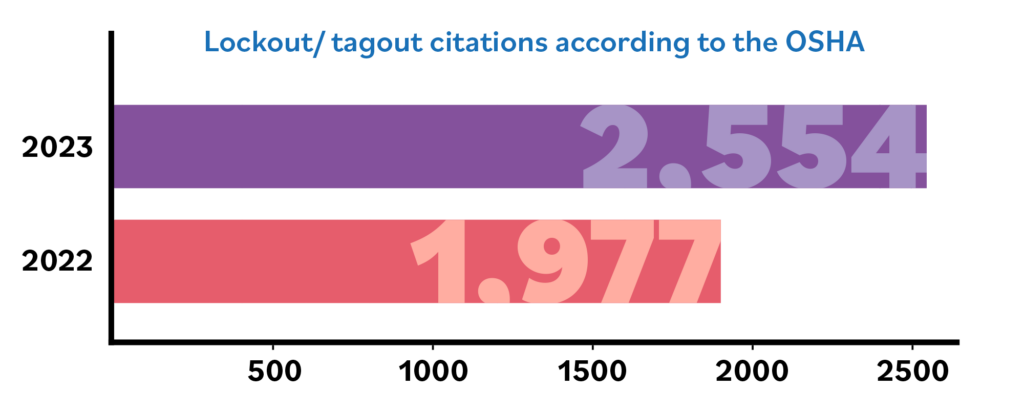

In 2022, it was the sixth most frequently cited OSHA standard according to their Top 10 Violations list, with 1,977 citations. By 2023, the number of violations had risen to 2,554. These violations often occur because companies fail to establish or adequately implement energy control procedures, provide sufficient employee training, conduct periodic evaluations or utilize appropriate LOTO devices. Industries such as plastics manufacturing, construction, chemical and oil and gas are particularly prone to these violations, with penalties reaching up to $13,260 per violation.

Given the frequency and severity of LOTO violations, companies must prioritize compliance to safeguard their workers and avoid substantial penalties. Adopting rigorous LOTO practices not only aligns with legal requirements but also fosters a safer, more efficient workplace.

What is Lockout/Tagout (LOTO)?

Lockout/Tagout (LOTO) is a critical safety procedure used to ensure that dangerous equipment is properly shut off and cannot be started up again prior to the completion of maintenance or servicing work. The primary purpose of LOTO is to protect workers from hazardous energy, which can include electrical, mechanical, hydraulic, pneumatic, chemical, thermal and stored energy sources. By isolating and rendering these energy sources inoperative, LOTO prevents accidental startup of equipment, which safeguards workers who might be in direct contact with machinery during maintenance.

Eric Conn, Chair of the OSHA/Workplace Safety Practice Group at Conn Maciel Carey LLP, highlights the significant attention OSHA pays to LOTO. He notes that no matter what reason OSHA has to inspect your site, they will check for LOTO. Since OSHA cites it frequently as a violation, it’s important that companies rigorously adhere to proper LOTO procedures to ensure compliance and protect their workers.

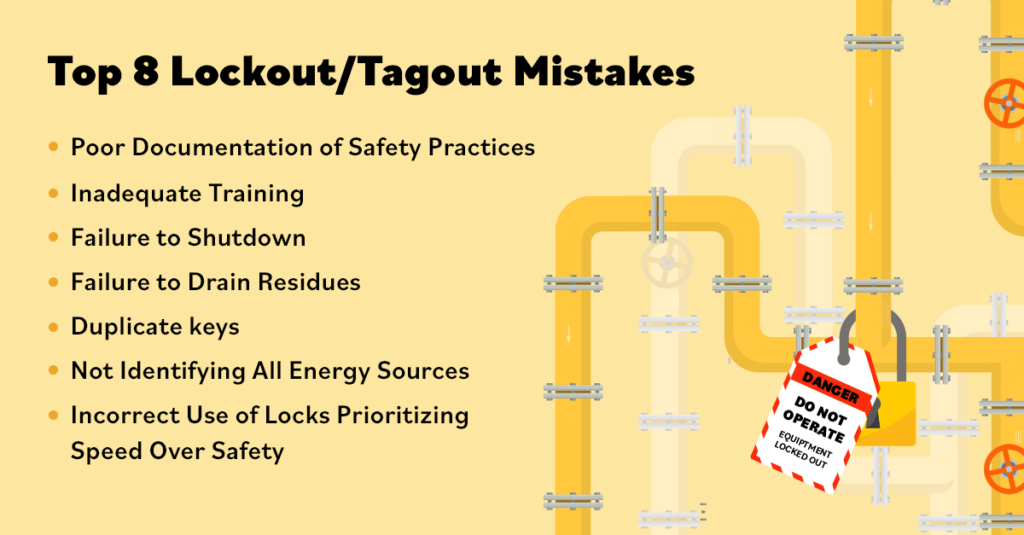

Common LOTO Mistakes and How to Avoid Them

Ensuring compliance with Lockout/Tagout procedures is crucial for maintaining a safe work environment. However, many employers make common mistakes that can lead to serious injuries or fatalities. Here are some frequent LOTO compliance errors and best practices for avoiding them:

Poor Documentation of Safety Practices

One of the most prevalent issues is the lack of formalized, written procedures for each machine and piece of equipment. Authorized employees must have clear, documented guidelines to follow.

Inadequate Training

Training must be comprehensive and include all employees who work around hazardous equipment, not just those directly responsible for applying locks and tags or other methods such as blocking the energy source. Everyone on the crew needs to understand the importance of LOTO procedures and how to execute them properly.

Failure to Shutdown

Failure to shutdown machinery completely before maintenance can lead to severe accidents, as it may still harbor hazardous energy that can cause unexpected startup or release.

Failure to Drain Residues

Failure to drain residual energy sources, such as fluids or gases, during LOTO procedures can result in hazardous releases that pose significant safety risks. This oversight can lead to serious injuries like burns or chemical exposure.

Duplicate keys

Having duplicate keys for locks used in LOTO procedures undermines the integrity of the lockout process, as it allows unauthorized individuals to potentially re-energize equipment.

Not Identifying All Energy Sources

Common places where energy sources are often overlooked include hidden hydraulic lines, residual pressure in pneumatic systems, stored electrical energy in capacitors and thermal energy in heated components. These oversights frequently occur during routine maintenance or when workers are under time pressure, leading to incomplete de-energization and increased risk of accidental energy release.

Incorrect Use of Locks

Incorrect ways to use locks in LOTO procedures include using locks that are not strong enough to withstand tampering, applying locks that are easily bypassed or removed and failing to use tags that clearly identify the worker responsible for the lockout.

Prioritizing Speed Over Safety

When the speed of completing a project takes precedence over safety, mistakes are inevitable. These errors can include using incorrect LOTO devices, failing to identify all sources of hazardous energy or completely bypassing safety procedures.

Failure to properly control hazardous energy can result in severe injuries such as electrocution, burns, crushing, laceration, amputation or fractures. For example, a steam valve might turn on automatically, burning workers repairing downstream connections or a jammed conveyor system might suddenly release, crushing a worker trying to clear the jam.

LOTO Tips and Best Practices

Ensuring Lockout/Tagout compliance requires meticulous planning and adherence to best practices. Key steps in the isolation procedure typically include:

- Announce Shutdown: Inform all affected employees of the impending shutdown and the reasons for it.

- Identify Energy Sources: Determine all potential sources of hazardous energy that need to be controlled.

- Isolate Energy Sources: Disconnect or make safe the equipment by removing all energy sources.

- Lock and Tag Energy Sources: Apply locks and tags to energy isolating devices to prevent accidental re-energization.

- Prove Effective Isolation: Verify that the equipment has been successfully isolated and de-energized.

- Conduct Regular Inspections: These inspections help identify potential issues before they lead to accidents.

- Conduct Periodic Audits: Conduct periodic audits to verify that all required procedures are in place, accurate, effective and optimized.

- Provide Comprehensive Training: All employees, regardless of their role, should receive thorough training on LOTO procedures.

- Maintain Documentation: Keep up to date records of audits and corrective actions taken, which are crucial for compliance and demonstrating dedication to safety.

How Intelex EHS Software Can Help

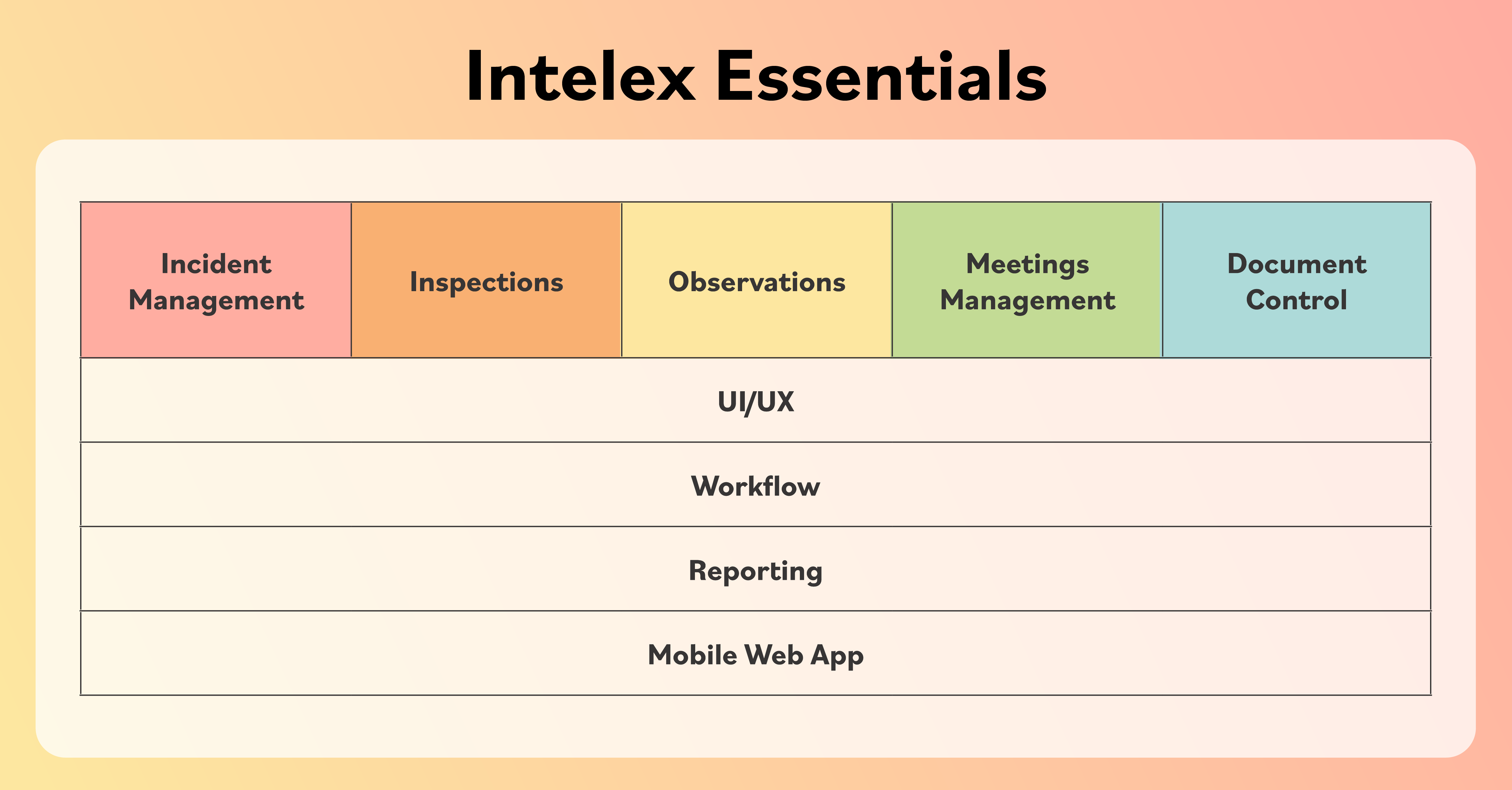

Intelex EHS Software offers a comprehensive suite of tools to help companies maintain LOTO compliance and enhance workplace safety. By automating procedures, managing training, facilitating inspections, controlling documents and reporting incidents, this software supports a proactive approach to safety management, ensuring that employees are protected from hazardous energy risks.

For example, proper training is crucial for effective LOTO compliance. Intelex Training Management software helps to ensure that all employees receive comprehensive training on LOTO procedures. The software maintains detailed training records, making it easy to track who has been trained when refresher courses are due.

Intelex Safety Inspections and Audit Management software are essential to facilitating these activities through automated scheduling and streamlined workflows. This helps identify potential issues before they lead to accidents, ensuring that all procedures are up to date and effective.

Keeping all necessary documentation organized and easily accessible is another key aspect of LOTO compliance. Intelex Document Control software allows companies to store and manage all relevant documents in a centralized location. Manual processes are often time-consuming and error-prone; while Intelex software ensures that employees can quickly access the latest version of the information they need to perform their tasks safely.

Effective incident reporting and analysis are critical for preventing future occurrences. Intelex Incident Reporting and CAPA software help organizations understand the root causes of near misses or accidents and implement corrective actions to prevent similar issues from happening again in the future.

Additionally, Intelex Job Safety Analysis software significantly enhances workplace safety by reducing risk and boosting productivity. It helps workers identify, understand and control hazards associated with any job or task, effectively reducing incident and injury rates. Tracking down and managing the causes of incidents through job safety analysis can drastically reduce workplace-related injuries and illnesses, supporting compliance with OSHA job hazard analysis requirements and increasing uptime.

By integrating all these functionalities, Intelex EHS Software ensures a comprehensive approach to workplace safety, helping organizations protect their employees and enhance operational efficiency.

Conclusion

LOTO compliance is essential for preventing serious injuries such as electrocution, burns, crushing and amputations. Ensuring that all energy sources are identified, procedures are clear and documented and employees are properly trained can greatly reduce accident risk.

The integration of Intelex EHS Software can further enhance LOTO compliance and overall workplace safety. By developing and automating procedures, managing training, facilitating inspections and audits, controlling documentation and providing robust incident reporting tools, Intelex EHS Software supports a proactive and systematic approach to safety management.

Making LOTO compliance a top priority not only aligns with legal requirements but also fosters a safer, more efficient workplace. With advanced tools like Intelex EHS Software, companies can ensure they are doing everything possible to protect their workers and maintain a safe working environment.